General Motors disclosed on September 15, 2025 that its Wentzville, Missouri assembly plant will idle most of its workforce for three weeks (Sept. 29–Oct. 19) due to parts shortages.

The plant, which employs roughly 4,000 people and builds Chevrolet Colorado/GMC Canyon pickups and Chevrolet Express/GMC Savana vans, will resume full third‑shift production on Oct. 20.

In a joint letter to workers, the plant’s executive director and UAW Local 2250 chairman warned that nearly all production shifts would be affected, though some supporting departments (skilled trades, stamping, body shop) may continue working.

Parts Shortage & Supply Issues

Local officials, including Mayor Nick Guccione of Wentzville, have pinpointed a lingering parts shortage as the trigger for the shutdown, though GM has not identified specific components.

GM spokesman Diana Forbes told trade press that “we have temporarily adjusted production schedules at Wentzville Assembly to address supply chain issues and align with overall business needs”.

Missing or delayed parts have forced GM to cut shifts. Company filings and union notices also note that unemployment and supplemental pay information is being provided to laid‑off workers. Such supply interruptions reflect broader logistics bottlenecks still plaguing the industry.

About the Wentzville Plant

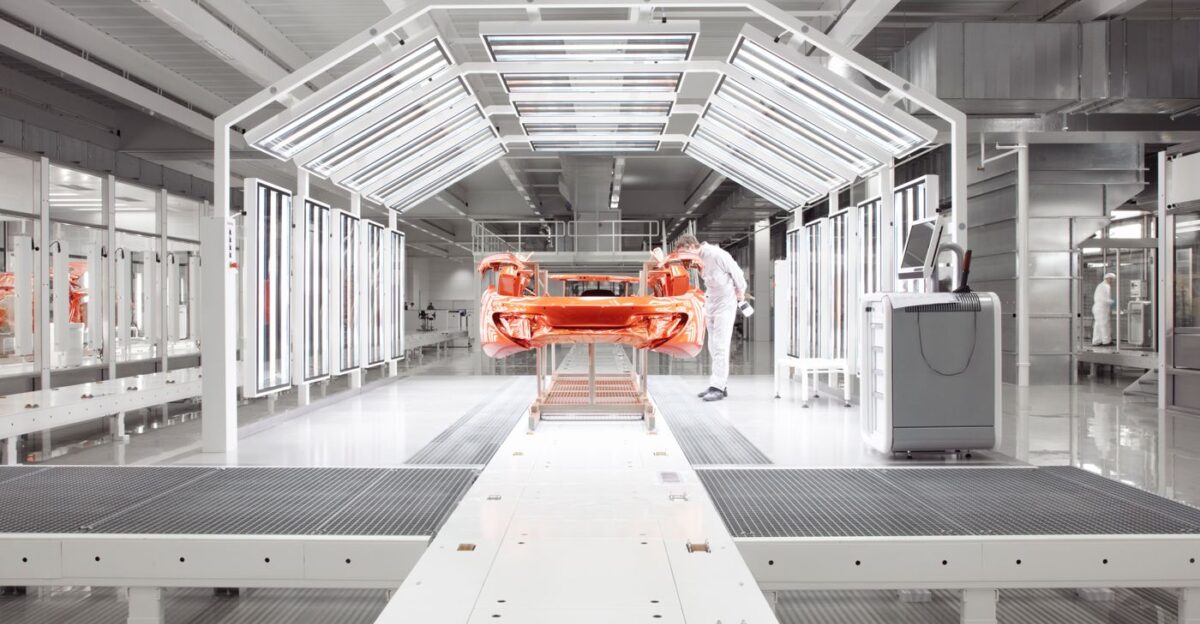

GM’s Wentzville facility (opened 1983) is a midsize‑truck and full‑size‑van hub. It manufactures the Chevrolet Colorado and GMC Canyon pickups and the Chevrolet Express/GMC Savana vans.

The plant supports over 4,000 workers on-site and leverages a vast supplier network in Missouri. State economic data show the plant underpins 12,241 jobs statewide and generates over $2 billion in annual GDP.

Those numbers capture direct and ripple effects through local vendors and communities. In 2019, GM invested $1.5 billion there to build next‑generation trucks, underscoring the facility’s importance.

Regional Economic Impact

Wentzville is a manufacturing anchor for the St. Charles County/St Louis region. Missouri officials emphasized the plant’s outsized role. Governor Mike Parson noted that the $1.5 billion retooling (2019) yielded “4,000 good-paying jobs that will benefit not only Wentzville, but every corner of the state”.

St. Charles County Executive Steve Ehlmann likewise praised GM as “our community’s largest employer” and said its investment “highlights the strength of advanced manufacturing in St. Charles County”.

In Wentzville itself, Mayor Guccione had called GM “a strong employer” whose commitment “speaks volumes” for the city. The sudden shutdown, even if temporary, therefore unsettles families and local businesses that depend on GM wages and supplier contracts.

Voices of the Workforce

For many employees, the news brought anxiety. While GM and the UAW have promised unemployment and “supplemental pay,” factory workers face a sudden income gap in late September.

In union communications, the leaders thanked workers for their “understanding and flexibility as we work through this issue,” acknowledging the strain of lost shifts.

Outside the halls, a laid‑off assembler described the looming break from routine as frightening: “This is how I put food on the table,” one worker told reporters (anonymously). For veteran laborers with families in Wentzville, the shutdown highlighted the precariousness of even “full employment” in today’s auto industry, especially after surviving the 2024 UAW strike and pandemic upheavals.

Union Response and Communication

United Auto Workers leaders moved quickly to manage the disruption. A joint notice from UAW Local 2250 Chairman Jon Daugherty and GM Plant Executive Eric Shelhorn spelled out which departments would be idled.

“Although this temporary layoff will affect the majority of our team on all three shifts,” they wrote, “skilled trades, stamping, body shop, final process, and those groups that support these departments may have work available during this time”.

Union reps have also used social media to give workers scheduling updates. For example, UAW trustee Shana Shaw posted that stamping and body‐shop teams would remain on shift to support other lines, and that remaining employees should await leader instructions for any work during the gap.

GM’s Official Statement

General Motors has tried to allay concerns. Spokespeople emphasize that the cutback is temporary and tied strictly to parts availability. Diana Forbes reiterated that the plant will “temporarily adjust production schedules … to address supply chain issues”.

A GM official (at the nearby Fairfax, Kansas City, plant) also confirmed no layoffs there, underscoring that Wentzville’s pause is an isolated scheduling measure.

GM’s media materials note that production is slated to resume by Oct. 20. In July 2024, for instance, the plant similarly halted when a seat‑supplier strike hit output, and “production at Wentzville … came to a halt due to a labor dispute at its seat supplier” (Lear Corp.); GM then hoped “both sides work quickly to resolve their issues so we can resume” assembly.

Recurring Production Disruptions

Industry observers note Wentzville’s shutdown has precedents. The plant was shut in late 2021 amid the global semiconductor shortage, and again in July 2024 during a UAW‑led strike at Lear (the seat manufacturer).

UAW Region Director Brandon Campbell explicitly blamed Lear for the 2024 stoppage, saying Wentzville was “down thanks to Lear’s refusal to bargain a fair deal”.

GM’s July 2024 spokesperson, Kevin Kelley, likewise urged, “We hope both sides work quickly to resolve their issues so we can resume our regular production schedule,”. These episodes highlight how tightly Wentzville depends on its supplier network. Today’s parts shortage, like 2021’s, signals that even well‑capitalized, high‑volume plants are vulnerable to global supply chain jolts and labor disputes.

Supply Chain Challenges

Auto analysts say the bottlenecks at Wentzville reflect wider supply‐chain fragility. Last year’s UAW strike exposed how a halt at one supplier can ripple to assembly lines, and continued port congestion and material constraints have persisted.

A recent Institute for Supply Management survey noted U.S. factory production is still dented by hiring and pricing pressures, suggesting many plants are “not replacing people who have either left or been laid off”.

Experts warn that without policy relief, manufacturers struggle to adapt. ISM’s Susan Spence cautioned, “We believe that we’re not going to see a big turnaround until we have tariff deals set and not changing,” highlighting uncertainty in trade and sourcing.

Local and State Reaction

Missouri officials are monitoring the shutdown closely. Governor Parson, who helped secure Wentzville’s 2019 investment, has emphasized the plant’s importance to the state’s auto industry. He remarked that GM’s prior investment yielded “$1.5 billion and 4,000 good-paying jobs” spread across Missouri.

In recent days, he and state leaders have been in touch with GM and UAW 2250, emphasizing quick resolution.

St. Charles County executives pointed to GM’s commitment as validating Missouri’s workforce: County Executive Ehlmann said GM’s continued growth “highlights the strength of advanced manufacturing” in the region. On social media, local residents expressed concern – many posted messages like “Prayers up for the GM workers in Wentzville” as word spread.

Broader Industry Trends

The Wentzville pause comes amid mixed signals in U.S. auto markets. General Motors and other automakers are already cutting EV production in response to waning incentives and slow consumer uptake.

In a September GM press release, North America chief Duncan Aldred noted that EV demand surged ahead of credits but then “there’s no doubt we’ll see lower EV sales next quarter after tax credits end Sept. 30,” adding “we will almost certainly see a smaller EV market for a while, and we won’t overproduce”.

CEO Mary Barra likewise said last winter, “The $7,500 tax credit is driving demand; without that, that’ll slow”. Even GM’s ICE lineup is adjusting — inventories of Express/Savana vans have been constrained by supplier issues.

Policy and Market Pressures

Automotive economists point to policy headwinds and market factors compounding the plant’s woes. Alliance for American Manufacturing president Scott Paul said recent auto job losses should spur “concluding tariff actions and trade deals to provide businesses with the certainty they need” and noted that “manufacturing will be treading water until we see those changes”.

Meanwhile, rising interest rates have cooled U.S. auto sales generally. A September Bureau of Labor Statistics report showed the transportation equipment sector shed jobs in August, largely due to strikes but also due to slower production at some plants.

The AFL‑CIO has decried recent federal policies, noting that stopping infrastructure projects and undoing EV incentives have contributed to manufacturing layoffs.

Investment and Community Support

Missouri’s past attraction of GM investment underscores the stakes. State officials once championed Wentzville as a job generator – Lieutenant Governor Kehoe called GM’s reinvestment “proof positive” that Missouri’s economy relies on an “auto industry driving force”.

Local economic development groups are now scrambling to assist displaced workers. Missouri One Start (which organizes workforce training) has reminded GM hires that retraining grants should layoffs extend beyond a few weeks.

Community college programs have held informational sessions on upskilling and temporary employment. Many families are also reaching out to churches and nonprofits for short‑term aid.

Labor and Manufacturing Culture

Wentzville’s predicament also reignites debates about manufacturing’s future in America. For decades, a GM job meant stability and middle‑class security; today, younger workers see careers as more fluid.

Some locals noted that, unlike past eras, even tenured assemblers can’t assume continuous work: as one 30‑year UAW member put it, “A lifetime on the line now feels temporary.”

Labor scholars observe that U.S. factories are under pressure to adopt flexible scheduling and more automation, eroding the traditional identity of blue‑collar labor. Despite a renewed pride in “made-in-America” products, public polling shows many Americans favor retraining workers out of declining industries.

Turning Point in Context

The September idling may be a turning point for GM and its workers. It comes at the nexus of EV policy uncertainty and shifting corporate strategy. GM has already delayed several EV projects (e.g., pausing a Chevy Bolt assembly shift) in anticipation of a demand drop.

Wentzville itself was once slated to build an electric passenger van by 2026, a plan now on hold. The timing of the shutdown—right as EV tax credits expire—highlights that GM is recalibrating its production: it warns of a “rough patch” after subsidies end.

For Wentzville, that may mean not just a one‑month pause, but a potential shift to new models or technology. In this sense, the plant’s forced downtime is more than a blip.

Resume Plans & Next Steps

According to union notices, GM plans to bring Wentzville back online with third‑shift work on Oct. 20. In the interim, the company is working with suppliers to clear the bottleneck.

Analysts will be watching whether GM alters inventory policies for Colorado/Canyon trucks or Express/Savana vans. The automaker also pledged to reimburse any lost pay (per the contract’s “supplemental pay”) and to explore any available overtime once production restarts.

Meanwhile, UAW organizers continue communicating with members about seniority transfers or temporary reassignments to other GM plants, an option under the national agreement.

Supplier Relations and Strikes

Wentzville’s history shows how supplier disputes can freeze assembly. Last summer, a strike by about 500 UAW members at Lear’s Wentzville seating plant shut down GM’s line for weeks.

Labor leaders at that time blamed Lear’s stock buybacks, and unions pressed for fair wages, noting that “Wentzville Assembly is down thanks to Lear’s refusal to bargain a fair deal”.

GM acted as an intermediary in that dispute, echoing, “We hope both sides work quickly to resolve their issues”. In the current case, no public strike at a supplier is reported, but the analogy shows how sensitive GM production is to labor issues, even one step removed.

Future of Work & Labor Relations

Looking forward, both GM and the UAW are attuned to the plant’s future role. The 2023 UAW contract provides training upskilling for electrification in plants like Wentzville, acknowledging that some workers may transition to battery/EV projects elsewhere.

Economists note that without major new demand drivers, plants like Wentzville could face longer idles. Federal policy will also matter: national manufacturing support or new trade agreements could influence GM’s commitments.

For Wentzville families, recent months have reinforced a need for agility — whether through temporary moves to other jobs (e.g., rehire at truck plants elsewhere) or leveraging enhanced unemployment. The UAW has meanwhile increased organizing of suppliers, hoping to prevent repeat stoppages.

National Manufacturing Landscape

This shutdown fits into a broader era of uncertainty for U.S. factories. Federal data show the transportation equipment sector (autos, aerospace) has lost thousands of jobs lately, due largely to strikes and slowing orders. In August 2025, for example, Boeing announced plans to cut 14,500 jobs in that sector.

The overall manufacturing unemployment rate ticked up, and industry groups warn that without clear policy (trade deals, infrastructure), “manufacturing will be treading water” nationally.

GM’s Wentzville plant, once emblematic of resilient midwestern industry, now resembles many American factories: profitable but vulnerable to global shifts. As one economist put it, U.S. manufacturing is not declining everywhere, but “the heart of working‑class America now beats elsewhere” outside the traditional plants.

Broader Reflections

In the long view, the Wentzville shutdown is more than a local glitch — it’s emblematic of how manufacturing jobs in the U.S. are changing. The “Mini Nugget” of insight here is that stability in factories can no longer be assumed.

Even a plant invested in with billions and protected by strong local support can pause under combined pressures of supply chains, labor, and shifting demand.

For the workers and families, the shutdown underscores a cultural shift: factory work once promised multi-decade tenure, but today even secure jobs can be interrupted. Policymakers and industry leaders may see Wentzville as a lesson that revitalizing manufacturing will require trade certainty, investment in skills, and adaptive corporate strategy.