Tariffs have emerged as a significant factor affecting U.S. manufacturing, with recent policies leading to job displacement and operational relocations. The implementation of tariffs initiated by the Trump administration created a wave of uncertainty that reverberated throughout supply chains, influencing hiring practices across various sectors.

As companies grapple with increased costs, the manufacturing landscape is undergoing rapid changes, resulting in substantial job losses. A prominent example is the recent closure of a Brooklyn-based company, resulting in 105 layoffs. These developments raise important questions about the long-term viability of U.S. manufacturing in the face of shifting trade policies.

The Unemployment Impact

The closure of the Brooklyn company highlights a broader trend where economic uncertainty, primarily attributed to tariffs, manifests in job losses. The fear of escalating costs has made manufacturers reluctant to expand their workforce, leading to a slowdown in hiring.

Analysts note that this cautious approach is not isolated to manufacturing; related sectors such as logistics and retail are also feeling the pinch. As one local worker expressed, “We had hoped for stability, but with tariffs looming, many of us are left anxious about our jobs.” This sentiment underscores the profound impact tariffs have on individual livelihoods.

Historical Perspective

To understand the implications of recent tariffs, it’s essential to look at the historical context of U.S. manufacturing employment. From a peak of 19.5 million jobs in 1970, manufacturing employment has been in steady decline, mainly due to the impact of automation and globalization. Tariffs, while intended to protect domestic industries, are now compounding these challenges.

Experts from the Federal Reserve Bank of St. Louis emphasize that tariff policies have intensified this downward trend. As these policies disrupt established supply chains, they exacerbate existing vulnerabilities within the manufacturing sector. This backdrop sets the stage for the current upheavals faced by manufacturing workers.

Challenges for Industries

The manufacturing landscape is increasingly characterized by pressure stemming from rising costs associated with tariffs and other trade-related issues. Industries such as automotive and electronics are particularly affected, where the price of imported raw materials has surged, forcing companies to rethink their strategies.

Many are diversifying their supply chains to mitigate these risks. “We’ve had to look beyond our borders for suppliers to keep our costs in check,” a manufacturing executive noted, encapsulating the adaptive measures being taken. This shift not only influences operational strategies but also poses a challenge to the traditional reliance on local manufacturing.

Brooklyn Closure

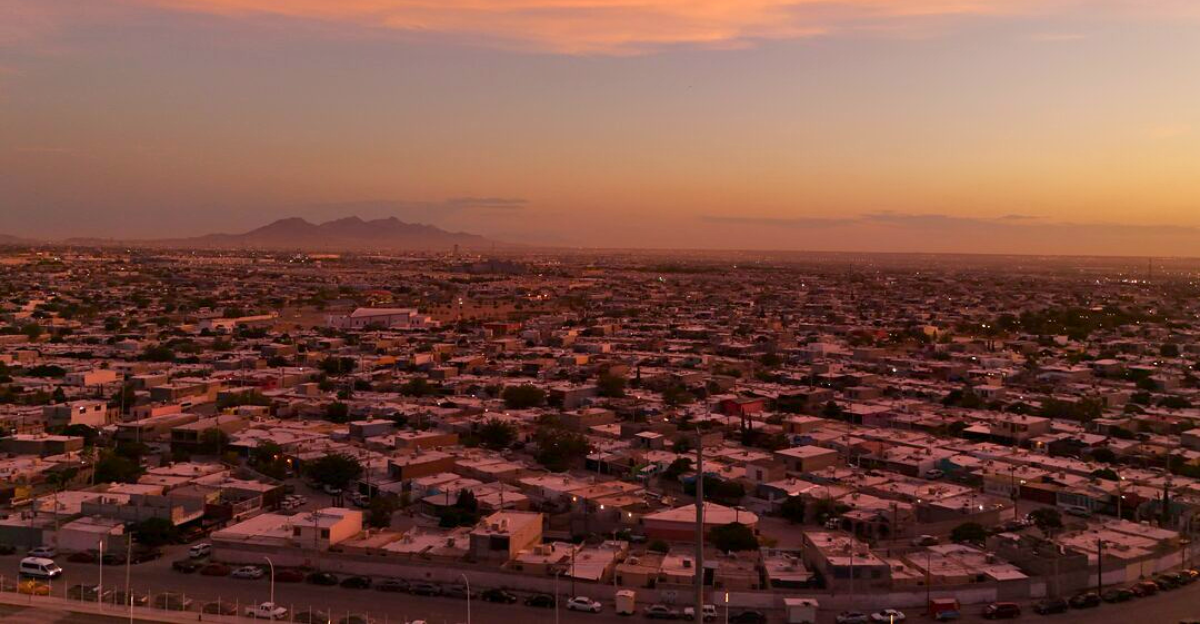

Recently, a Brooklyn-based manufacturing company made the difficult decision to close its facility, laying off 105 workers due to the burdens imposed by tariffs. The operations are shifting to Mexico, serving as a stark example of how trade policies can dramatically alter the landscape for local economies. One former worker shared, “It feels unreal to lose our jobs like this.

All we wanted was to work hard and support our families.” This closure echoes a rising trend wherein manufacturers relocate to regions with more favorable economic conditions, stripping communities of vital job opportunities and financial stability.

Regional Effects

The impact of tariffs extends well beyond individual companies, affecting entire manufacturing hubs throughout the U.S. Regions such as the Midwest and Southeast, heavily reliant on imported goods, face daunting tariff burdens. These areas have seen significant downturns in job availability as manufacturers struggle to absorb the higher costs.

The Richmond Fed highlights that the closures and job losses create a ripple effect, undermining local economies built around manufacturing. “These decisions force families to make tough choices,” remarked a local economic analyst, illustrating the broader implications for community resilience.

The Human Cost

Job losses in places like Brooklyn resonate deeply within affected communities. The layoffs are not merely statistical; they represent real people grappling with financial uncertainty and emotional distress. A local employee reflected, “This job was my life, and now I feel lost.” This emotional toll highlights the personal consequences of federal policy decisions.

Communities left reeling from job losses must navigate the challenges of decreased economic activity, further stressing the importance of considering the human impact when implementing trade policies. It’s a stark reminder of the high stakes involved in deregulation.

Competitors Adapt

In response to the evolving trade landscape, various competitors are recalibrating their operational strategies. Many are pursuing supply chain diversification or seeking alternative suppliers to mitigate rising costs driven by tariffs. Particularly in industries such as automotive and electronics, this trend is becoming increasingly evident as companies strive for resilience amid uncertainty.

“We’ve had to become more creative in how we source materials,” one industry leader shared, emphasizing the necessity of adaptability. Such strategic pivots showcase the industry’s response to navigating the complexities introduced by tariffs and economic volatility.

Broader Economic Implications

The imposition of tariffs carries far-reaching macroeconomic consequences. Consumers can expect increased prices as manufacturers pass on higher costs, while U.S. exports may suffer from retaliatory measures taken by trading partners. Economic analysts warn that this interconnectedness means tariffs could stifle growth not just in the manufacturing sector but across the entire economy.

“It’s a chain reaction; when some sectors hurt, others follow,” stated an economic expert. This broader outlook emphasizes that trade policy decisions can have profound implications well beyond their immediate targets.

Automation Surge

Amid the uncertainties unleashed by tariffs, many companies have turned to automation as a strategic response. By investing in technology, businesses aim to reduce labor costs and enhance efficiency, driven by the need to adapt to higher operational expenses.

However, this shift towards automation raises concerns about further job displacement within the manufacturing sector. “I worry about where the next generation of workers will fit in,” noted a factory owner. This sentiment reflects a broader fear that automation may exacerbate existing employment challenges while simultaneously aiming to sustain profitability.

Stakeholder Frustration

Frustration among stakeholders, business leaders, policymakers, and workers is palpable as the uncertainty surrounding tariffs persists. The lack of coherent trade policies hinders long-term planning and investment, leaving companies to scramble and navigate a volatile environment.

As one frustrated executive stated, “We need clear guidelines to plan for the future; right now, it feels like we’re reacting instead of strategizing.” This sense of confusion complicates efforts to stabilize the manufacturing sector, further entrenching the adverse effects initiated by tariffs.

Shifts in Leadership

With companies facing unprecedented challenges due to tariffs, some are undergoing leadership shifts to address the strategic need for adaptation. New leadership often brings fresh perspectives on navigating the rugged landscape of tariffs and their implications.

An industry analyst remarked, “Companies must evolve in their thinking and approach to survive.” Such strategic leadership changes can significantly reshape operational management, as organizations strive to align with evolving market dynamics and shifting stakeholder expectations. These shifts underscore the importance of agile leadership during periods of economic turbulence.

Recovery Strategies

As manufacturers seek pathways to recover from the ramifications of tariffs, diversifying supply chains and exploring new markets emerge as viable strategies. However, implementing these approaches requires a significant investment of time and resources, complicating immediate recovery efforts. “We’re trying to pivot, but the pace of change is daunting,” indicated a manufacturing director.

This necessity for investment underscores the long-term commitment manufacturers must embrace to navigate the post-tariff landscape. While solutions exist, the journey toward stabilizing operations remains fraught with uncertainty.

Expert Predictions

Experts predict that the adverse effects of tariffs will linger within the manufacturing sector for the foreseeable future. The implications for employment and economic growth remain uncertain, keeping stakeholders on edge.

As an economist pointed out, “The long-term effects of these policies will take time to unfold, making it difficult for companies to plan.” This unpredictability underscores the ongoing need for vigilance among businesses and their employees, particularly in an environment where tariffs can impact operational viability.

Future Reflection

Looking ahead, the pressing question remains: Will tariffs achieve their intended goals of bolstering U.S. manufacturing? The ongoing uncertainty and economic shifts suggest a complex and precarious future for the sector. “It’s hard to see where we go from here,” a manufacturing worker lamented, encapsulating the uncertain road ahead.

As industry players navigate these turbulent waters, clarity on trade policy direction will be critical to fostering a more stable marketplace. The path forward is fraught with challenges, but it also presents opportunities for rebirth.

Political Ramifications

The political implications of tariffs are substantial, reflecting broader debates on trade policy and the delicate balance between national interests and global economic realities. Policymakers are tasked with crafting regulations that protect domestic industries while promoting growth in a competitive international environment.

“We must find solutions that support our workers while acknowledging the realities of global trade,” stated a political analyst. These discussions highlight the intricate interplay between economic strategy and legislative action, underscoring the importance of informed dialogue in shaping a sustainable future.

Global Reactions

Internationally, the implementation of tariffs has triggered retaliatory measures from trading partners, resulting in an increasingly complex and fraught global trade environment. The escalation of trade tensions has consequences, as countries grapple with reciprocal tariffs that further complicate export strategies.

“The global economy is feeling the effects, and this tension is not going away anytime soon,” emphasized a trade expert. This dynamic illustrates that tariff policies not only reshape national industries but also reverberate through the interconnected web of global trade relations.

Legal Challenges

The legal landscape surrounding tariffs is evolving, with notable challenges surfacing regarding their validity. A recent ruling by a federal appeals court deemed specific tariffs were imposed unlawfully, introducing further uncertainty into U.S. trade policy. “This legal back-and-forth leaves companies in a bind,” remarked a legal analyst.

As businesses attempt to navigate these complexities, the implications of legal challenges underscore the difficulties of managing compliance amid shifting interpretations of trade law. These factors contribute to additional pressures on the manufacturing sector, compounding an already intricate situation.

Cultural Shifts

The impact of tariffs embodies broader societal shifts, reflecting changing attitudes toward globalization and protectionism. The debates surrounding tariffs highlight the evolving perceptions of economic policies amid growing concerns about preserving domestic jobs and employment.

“As a nation, we need to rethink how we approach trade,” expressed a community advocate. This dialogue highlights the cultural dimensions that influence economic decision-making, underscoring the importance of considering the broader societal context in which tariffs are situated. It is an ongoing debate with implications beyond just economic statistics.

A Call to Action

As the manufacturing sector grapples with the ramifications of tariffs, there is an urgent need for stakeholders to engage in constructive dialogue and collaborative problem-solving. Finding common ground to address the economic, human, and political fallout requires collective efforts.

“If we want to rebuild, we have to come together and invest in our future,” stated a community leader. The path forward must blend strategic investments, innovative approaches, and a commitment to social responsibility as industries navigate the challenges posed by tariffs and seek sustained growth in the face of adversity.