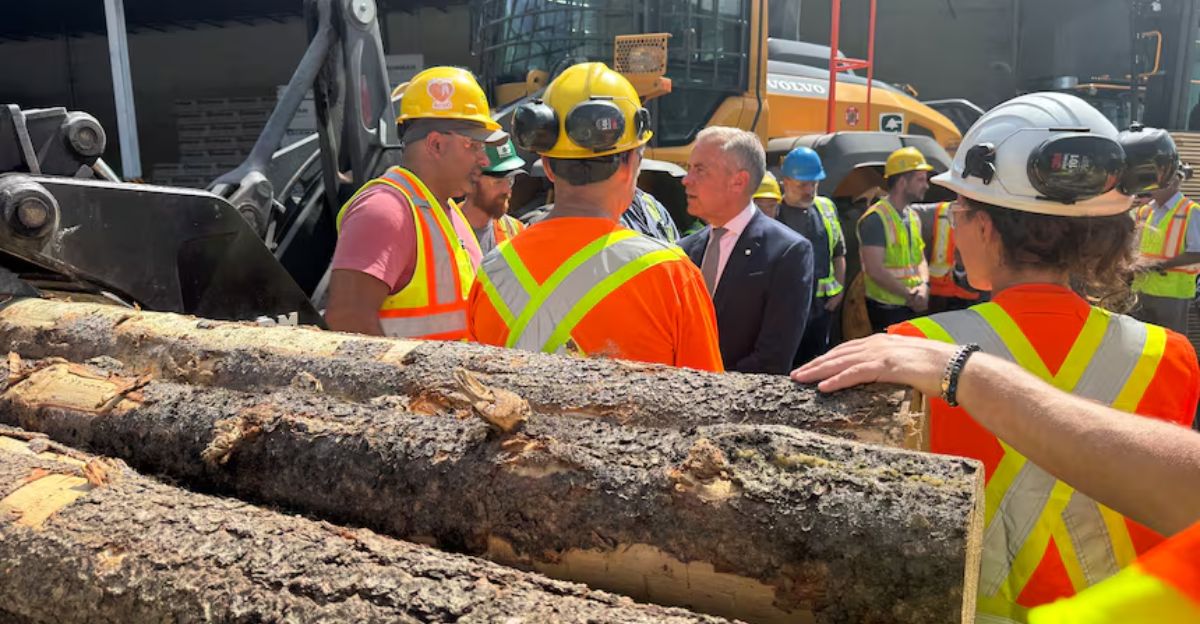

Stacks of lumber sit under an overcast Illinois sky, marked with prices that jumped in a matter of days. Forklifts move pallets toward waiting trucks as contractors recalculate bids mid-project. Canadian softwood, which supplies roughly one-third of U.S. homebuilding needs, has faced significant tariff increases, adding thousands to the cost of a typical new home. For many buyers, that shift ends the deal before construction begins.

But one regional supplier didn’t survive the spike—what caused its collapse?

Costs Surge

Construction inputs have jumped dramatically over the past several years as tariffs forced suppliers to absorb higher prices. Canadian lumber tariffs have escalated substantially, with concrete and household appliances also facing significant cost pressures.

These increases compound into thousands added to every new home. Builders face the difficult choice of absorbing rising costs, passing them along to customers, or slowing production. For smaller suppliers, the sustained cost pressure can rapidly erode margins and destabilize cash flow.

Trade Fight

The tariff dispute traces back to U.S. claims that Canada subsidizes its lumber industry unfairly. The U.S. responded with duties, significantly impacting a material that supplies roughly one-third of all wood used in U.S. homebuilding.

This policy significantly shifted construction costs and reshaped purchasing strategies for distributors. Tariffs also created volatility rather than stability, leaving firms unsure how to price bids or manage inventory when the cost of essential inputs could spike unpredictably.

Builders Squeezed

Tariffs and trade policies are estimated to add between $7,500 and $10,000 in added costs to a typical new home, with building materials representing a substantial portion of this increase. These numbers matter because every $1,000 increase in median home price can price out approximately 106,000 potential buyers from the market.

Builders that operate under fixed-price contracts are uniquely vulnerable because they cannot easily adjust pricing once bids are submitted. Volatile input costs, tight margins, and slower sales place both builders and suppliers under significant financial strain.

Bankruptcy Reveal

On December 3, 2025, North American Builder’s Supply filed for voluntary Chapter 11 bankruptcy in the U.S. Bankruptcy Court for the Northern District of Illinois. According to court filings, the company reported estimated assets between $500,001 and $1 million, with estimated liabilities between $1,000,001 and $10 million.

Despite the filing, the company remains open and intends to reorganize its operations. The company currently has approximately 49 unsecured creditors. The decision highlights how tariff pressures and material inflation can create unsustainable debt burdens for mid-sized suppliers.

Home Depot Rival

North American Builder’s Supply occupied the same product category as national chains such as Home Depot and Lowe’s, selling lumber and building materials to local contractors and commercial customers. Described as a “regional supplier,” the company lacked the scale advantages enjoyed by big-box retailers.

Its limited leverage restricted its ability to negotiate pricing or diversify supply, leaving it more exposed to spikes in lumber, concrete, and other material costs. The tariff environment magnified its disadvantages in a highly competitive market.

Human Pressure

Fixed-price contracts create intense pressure for builders and suppliers alike. Contractors can bid on a project months before materials are ordered, only to face dramatically higher costs when construction begins. As industry observers have noted, prices can shift significantly between bidding and execution.

These shifts compress margins, slow payments, and increase the likelihood of delayed or defaulted invoices. Suppliers like North American Builder’s Supply feel the downstream effects as customers struggle to manage unpredictable expenses.

Big-Box Buffer

Large retailers possess risk buffers that smaller suppliers cannot match. Major home improvement chains like Home Depot have committed to increasing domestic sourcing to insulate themselves from tariff exposure.

Lowe’s carries substantial inventory—reported at $17.2 billion in recent filings—and continues to optimize its supply chain. These companies can dilute tariff exposure, negotiate better terms, and sustain volume even when material costs rise. For regional suppliers, a lack of scale and diversification means cost shocks hit harder and faster.

Housing Fallout

Higher material costs don’t just affect suppliers—they reshape the entire housing market. Estimates suggest that tariffs and inflation could add between $17,000 and $22,000 to the cost of a new home, significantly impacting affordability.

Using market sensitivity metrics, such increases could substantially reduce the pool of qualified buyers. Lower affordability weakens demand for new homes, reducing material orders and further tightening the financial environment for mid-sized distributors already battling rising costs.

Pattern Emerges

The bankruptcy of North American Builder’s Supply reflects a broader trend of cost-driven challenges across the construction industry. Input costs that climb significantly in short timeframes undermine budgets and timelines.

Builders may postpone or abandon projects, reducing inbound orders for suppliers. Companies with limited capital or credit reserves face greater vulnerability, raising concerns about additional insolvencies as tariff impacts and economic pressures persist.

Credit Strain

Court filings reveal how strained the company’s debt structure became. The filing indicates the company has approximately 49 unsecured creditors, indicating a fragmented debt base.

For a company with less than $1 million in assets and liabilities potentially reaching $10 million, this concentration underscores a thin financial cushion amid rising industry costs.

Reorganization Bid

By opting for Chapter 11, the company seeks time to restructure debts, renegotiate payment terms, and remain operational. The goal is to stabilize cash flow while continuing to serve existing customers. Restructuring may include modified repayment plans or operational changes designed to withstand ongoing cost volatility.

Given the small size of the firm and its heavy debt burden, success will likely hinge on whether tariff and cost pressures ease enough to restore sustainable margins.

Competitive Crossroads

Regional building suppliers often thrive by offering personalized service, local relationships, and flexible credit. Yet those strengths can convert into liabilities when material prices surge quickly. Contractors struggling with cost volatility may delay or reduce payments, shifting financial stress onto suppliers.

Meanwhile, large retailers can leverage purchasing power, hedging capabilities, and logistics networks to maintain competitiveness. Regional firms face a strategic dilemma: specialize, seek partners, or risk being squeezed out of the market entirely.

Expert Doubts

Analysts caution against attributing every bankruptcy solely to tariffs, pointing to broader inflation, higher interest rates, and demand fluctuations. However, trade policies have undeniably added cost burdens that destabilize already-fragile firms. Industry groups warn that continued volatility may lead to more insolvencies, especially among suppliers operating on thin margins.

As housing affordability erodes and demand softens, the question becomes whether policy changes or market adjustments will arrive before more companies are pushed toward financial distress.

Who’s Next?

The bankruptcy of North American Builder’s Supply highlights how regional suppliers can be overwhelmed by the combined forces of tariffs, inflation, and reduced housing affordability.

National chains with diversified sourcing and substantial inventories continue to weather the storm, while smaller firms carry more risk with fewer resources. If tariff and cost pressures persist, additional suppliers could find themselves facing significant liabilities and limited pathways to recovery. The industry now watches closely for the next casualty.

Sources:

U.S. Bankruptcy Court for the Northern District of Illinois, Case No. 1:25-bk-18572; North American Builder’s Supply, Inc. Chapter 11 Filing (December 3, 2025)

Cotality/CoreLogic Housing Affordability Analysis; “Will Trump tariffs harm home affordability?” (February 9, 2025)

National Association of Home Builders (NAHB) Tariff Impact Study; NAHB Chief Economist Rob Dietz tariff cost projections on home construction ($7,500-$10,000 per home estimate)

Steve Martinez, Tradinds Generaling, Idaho; NAHB Testimony on Fixed-Price Construction Contracts and Tariff Volatility (2024-2025)