America’s factories are dealing with a historic worker shortage, with the economic impact estimated at more than $1 trillion. Industry experts warn that without quick solutions, U.S. manufacturing could lose its competitive edge in the global market.

“AI is not just a tool, it’s a necessity for survival in today’s manufacturing landscape,” one executive explained. With pressure mounting, many companies now see artificial intelligence as their only way forward. That leads to the next question—how deep is the risk?

Productivity Is Slipping as Jobs Stay Empty

This shortage is more than numbers on a page. Factories across the country are struggling to maintain production levels, leaving shelves emptier and deadlines harder to meet. Many companies report constant hiring difficulties, with positions staying open for months.

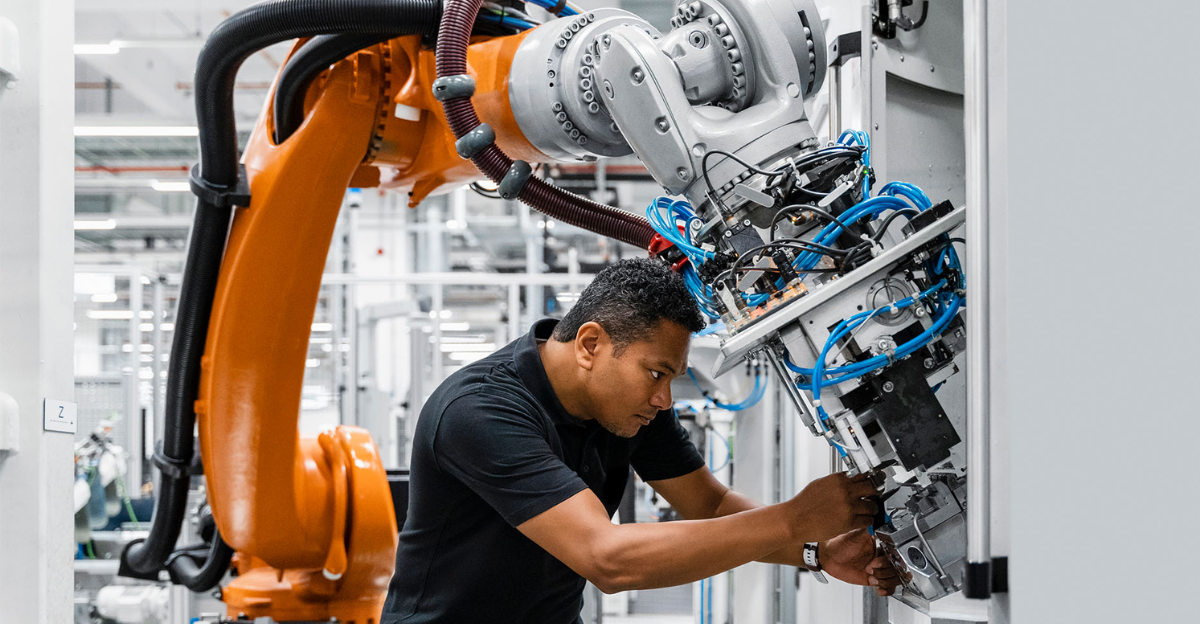

To stay afloat, manufacturers are being pushed to consider alternatives they once avoided. For many, the answer is leaning heavily on technology. This is where AI enters the picture, but it’s not the first time factories have turned to machines.

From Old-School Labor to New-School Machines

Factories once ran on stable workforces supported by simple machines. Incremental automation helped, but people remained at the core of production. That picture has changed in the last decade as costs climbed and competition grew fiercer.

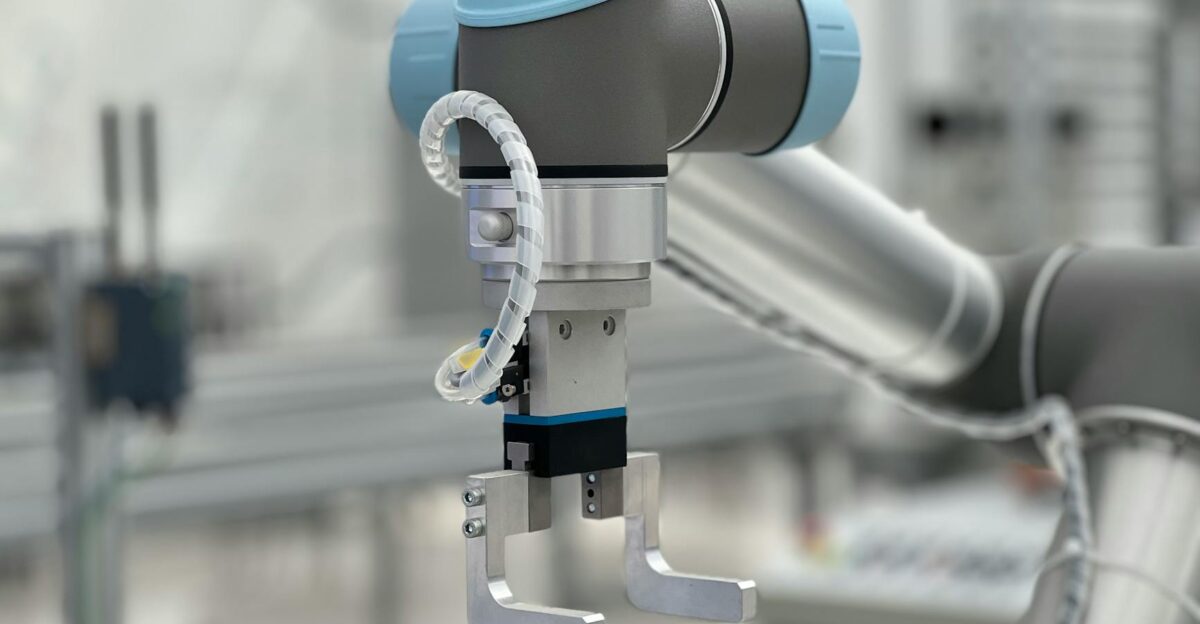

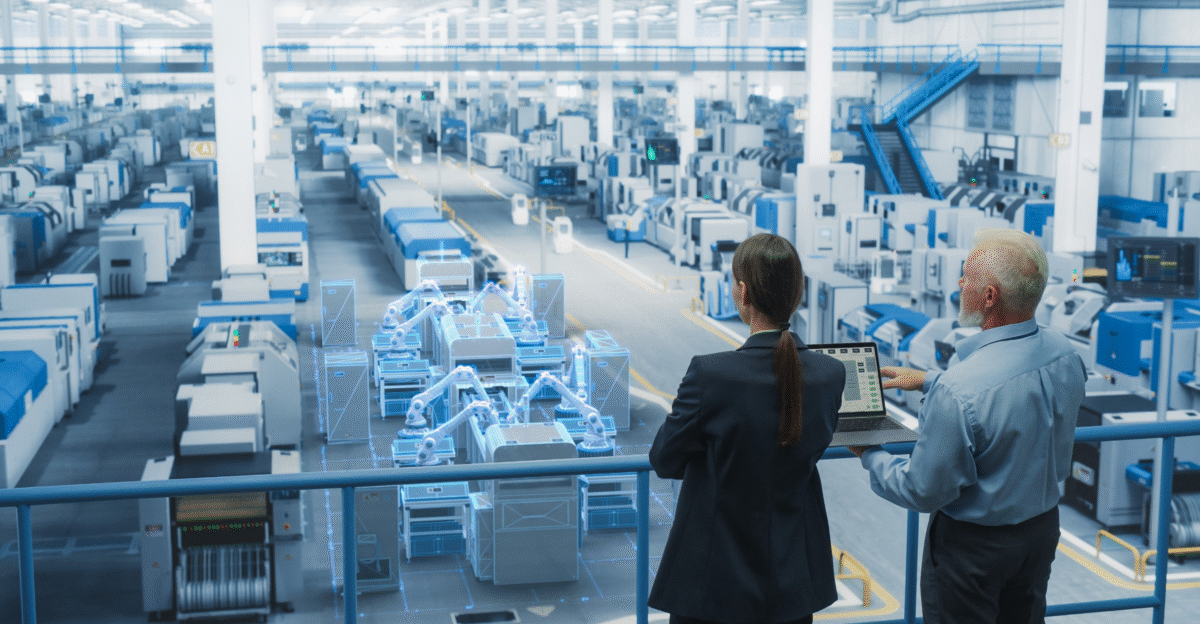

Now, digital transformation and robotics are no longer side projects; they’re main strategies. Manufacturing leaders are adopting new technologies to stay relevant. Still, automation doesn’t exist in a vacuum. External pressures are making the crisis worse, forcing U.S. companies to act even faster.

Global Pressures Make a Tough Job Tougher

U.S. manufacturers are being squeezed by global instability, supply chain disruptions, and workforce changes at home. Retiring baby boomers are leaving major gaps, while younger workers show less interest in factory jobs.

This combination creates a storm of challenges for employers. Without adaptation, many risk falling behind international competitors. The urgency is clear: adapt to survive. That urgency is why many factories are shifting their strategies in 2025 and looking directly to AI for solutions.

Factories Are Turning to AI at Full Speed

In 2025, AI adoption in manufacturing has surged like never before. Robots powered by AI now handle repetitive tasks, while predictive software monitors machines to prevent costly breakdowns. These tools keep plants moving when human labor falls short.

With AI woven into daily operations, factories can keep production running smoothly. And the adoption isn’t isolated to a few hotspots. The next slide shows how the shift is spreading across America’s industrial map.

AI Is Everywhere, From Detroit to Dallas

From Michigan’s auto plants to electronics hubs in Texas, AI is showing up in factories of every kind. Whether producing cars, semiconductors, or heavy machinery, companies are finding ways to integrate digital tools into daily workflows.

This broad adoption signals that AI is not a niche solution. It’s becoming the backbone of modern manufacturing across the country. Yet while the technology takes hold, its human impact is just as important. Workers themselves are starting to share their perspective.

Workers Say AI Is Changing Daily Life

Factory staff are seeing their jobs evolve in real time. “AI helps us keep up with demand, but it’s also changing the way we work,” said a Ford assembly line supervisor. The pace and structure of tasks feel different compared to past years.

For many, automation is both a relief and a worry. It reduces strain but also shifts traditional roles. These changes raise big questions about safety, fairness, and opportunity, and regulators are starting to pay close attention.

Regulators and Rivals Race to Keep Up

Leading companies such as Ford and Siemens are pushing AI forward, forcing rivals to follow or risk being left behind. At the same time, regulatory agencies are weighing in, setting safety rules and monitoring retraining standards as automation accelerates.

This dual pressure, competition on one side and oversight on the other, is shaping how fast AI spreads. And this shift is not happening in isolation. It is part of a much larger wave sweeping across the entire manufacturing industry.

The Bigger Picture: Industry 4.0 Is Here

The manufacturing world is deep into Industry 4.0, where AI, digital twins, and connected supply chains set the standard. This means machines talk to each other, production lines self-adjust, and factories become smarter by the day.

The result is a vision of factories that can react faster and produce more efficiently than ever before. But AI’s impact doesn’t stop at the assembly line. It is also reshaping the entire journey of goods, from raw materials to store shelves.

Supply Chains Get Smarter with AI

AI now tracks supply chains in ways humans never could. Predictive analytics help factories manage inventory more accurately, cut shortages, and streamline shipping routes. The result is fewer delays and faster deliveries to customers.

This makes U.S. manufacturers more resilient in the face of disruption. But with all these wins, tension is growing too. Workers worry about being left behind as technology spreads, and those concerns are becoming a major issue on the factory floor.

Workers Worry About What’s Next

Some workers fear AI could replace them, while others worry companies are moving too fast. Industry experts say that without strong communication and retraining, these tensions could grow worse.

Analysts emphasize that people remain a critical part of the system. Successful adoption depends on balancing machines with human skill. Executives are beginning to see this too, rethinking strategies and roles at the highest levels of their organizations. That brings a big shift in leadership focus.

Factory Leaders Reshape Their Playbooks

Executives are no longer treating AI as an experiment. Many are appointing Chief Digital Officers and hiring teams of data scientists to lead their transformation. This signals a clear, long-term commitment to digital strategies.

These moves are not just about technology—they’re about ensuring companies can survive the future of work. Leaders know success depends on guiding workers through change, which is why many are also launching large-scale training programs. That brings us to the next big step.

Companies Bet Big on Worker Training

Upskilling is now a top priority. Manufacturers are partnering with technical schools and online platforms to help employees gain new skills. Training focuses on operating, maintaining, and troubleshooting advanced AI systems.

This investment is designed to calm fears of job loss while building a workforce ready for modern factories. Still, not everyone is convinced. Analysts and experts remain cautious, stressing that AI alone cannot fix all the problems facing U.S. manufacturing.

Experts Say AI Isn’t a Magic Fix

AI may help factories run, but analysts stress it’s not the silver bullet. “Automation is a tool, not a panacea,” said a Deloitte analyst. Technology only works when paired with solid processes and a skilled workforce.

This means companies cannot rely on AI alone. They must invest in people and leadership if they want to close the labor gap. So, the big question remains: will AI truly be enough to bridge America’s trillion-dollar shortfall?

Can AI Truly Close the Gap?

The jury is still out. Early results suggest AI is making a major dent in labor shortages, but full closure will depend on government support, ongoing investment, and workers adapting to new roles.

Factories are testing the limits of what technology can achieve. The outcomes will shape not just manufacturing, but the future of work in America. That’s why policymakers are beginning to step in, hoping to guide the next chapter of this transformation.

Washington Steps Into the Debate

Federal and state officials are exploring ways to support the shift. Proposals include tax incentives for AI adoption and funding for retraining programs in STEM fields. The goal is to keep U.S. factories competitive while protecting workers.

This policy debate is far from settled, but the direction is clear: government sees AI as central to industrial strength. Other nations do too, and the global race is heating up. The next slide takes a look at that competition.

The World Is Racing Ahead on AI

America is not alone in this transformation. China and Germany are also pouring resources into industrial AI, raising the stakes for global leadership. Experts warn that lagging behind could mean losing manufacturing dominance.

This global contest is pushing calls for international standards to ensure safety and fairness. But competition isn’t the only concern. The rise of AI-powered factories also brings new questions about energy use and the environment, putting sustainability under the spotlight.

AI Factories Come with Energy Costs

AI systems make factories efficient, but they also consume significant energy. Cooling data centers and running advanced robotics require huge power supplies. Companies are now exploring renewable energy and innovative cooling methods to reduce emissions.

Balancing efficiency with sustainability has become a top priority. If done right, AI could both solve labor issues and support climate goals. This balance will also shape public opinion, which is shifting as younger generations see factories in a new light.

Young Workers See Factories Differently

AI is changing not just machines, but culture. Younger generations see factory work less as manual labor and more as tech-driven problem-solving. Traditional roles are fading, replaced by positions that require coding and digital skills.

This cultural shift is helping attract fresh talent to the industry. But it also underscores how deeply AI is reshaping work itself. That brings us to the final question: what does this all mean for the future of American jobs?

The Future of Work Is Being Written Now

America’s trillion-dollar labor shortage is forcing factories to rethink everything. AI is no longer optional—it’s central to staying competitive. But the challenge is balancing productivity with worker well-being in an economy that’s changing faster than ever.

The future of work will depend on how leaders, workers, and policymakers handle this shift. If done carefully, AI could turn a crisis into an opportunity, redefining what it means to work in American manufacturing. The story is still unfolding.