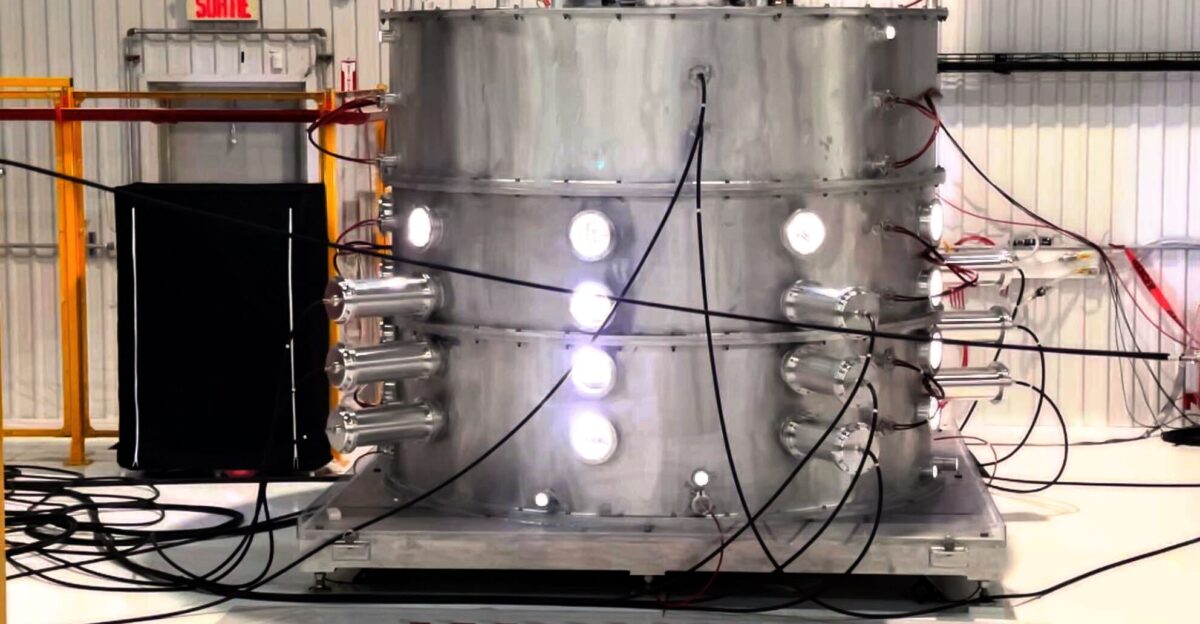

Fuse Energy Technologies has achieved a significant milestone in pulsed-power fusion engineering with TITAN, a revolutionary impedance-matched Marx generator that delivered 330 gigawatts of power in a controlled 100-nanosecond pulse. The results, published in the peer-reviewed journal Nature Scientific Reports in July 2024, represent the first successful demonstration of this technology class at scale and position the San Leandro, California-based startup at the forefront of fusion innovation.

The breakthrough centers on TITAN’s novel architecture: a 14-stage, 1-terawatt impedance-matched Marx generator comprising over 40,000 individual components. Weighing approximately 22 tons and containing roughly 20,000 liters of oil and 640 liters of continuously recirculating deionized water, TITAN represents a fundamental departure from conventional pulsed-power systems that have dominated fusion research for decades.

In controlled laboratory testing, the six-stage TITAN configuration consistently delivered 330 gigawatts of peak power to its matched resistive load, a burst equivalent to the combined electricity consumption of Tokyo, New York, Shanghai, and Dubai during that 100-nanosecond window. This achievement surpasses all previous demonstrations of impedance-matched Marx generator technology.

At the heart of TITAN lies a revolutionary triggering architecture never before successfully demonstrated at this scale. The device employs a 14-stage configuration in which only the first three stages require active external triggering. The remaining eleven stages self-fire automatically with less than 2-nanosecond timing jitter, solving a critical technical bottleneck that has constrained pulsed-power fusion for decades.

Traditional pulsed-power facilities, such as the Z machine at Sandia National Laboratories, operate at peak voltages exceeding 6-7 megavolts. TITAN dramatically reduces this to just 200 kilovolts, less than 3 percent of conventional systems. This significant voltage reduction directly translates to extended component lifespan, lower maintenance costs, and improved economic viability for future commercial fusion plants.

Impedance-Matched Design, Modularity, and Precision Engineering

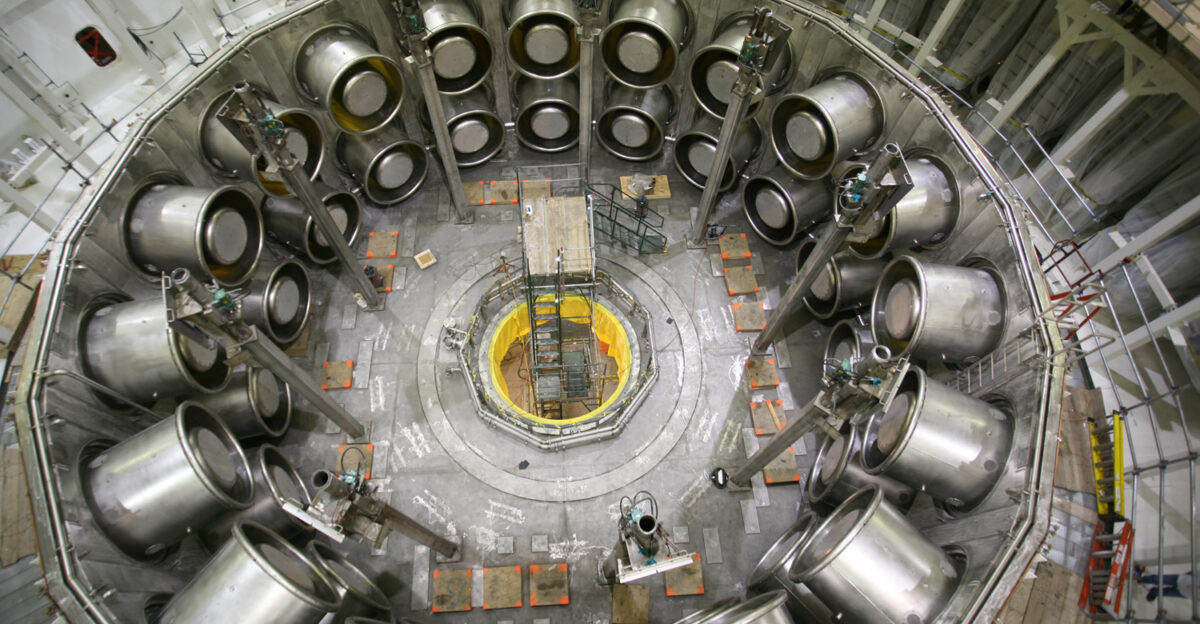

TITAN’s impedance-matched architecture represents a fundamental innovation. Each brick, or capacitor pair and switch assembly, maintains a specific impedance, with all 238 bricks organized into 14 series-connected stages to achieve a system impedance of approximately 2 ohms. This design enables connection of up to sixteen TITAN modules in parallel to create the planned Z-Star facility, a 15-plus terawatt intermediate power facility that could accelerate the timeline to net energy gain in fusion reactions.

This modular approach contrasts sharply with monolithic conventional systems, offering flexibility, scalability, and reduced construction risk. The impedance-matched design fundamentally changes how engineers approach large-scale pulsed-power systems by allowing multiple devices to share loads without the inefficiencies that plague conventional parallel-connected systems.

The Nature Scientific Reports publication emphasizes TITAN’s exceptional consistency. Experimental results correlated with computer simulations with greater than 99 percent accuracy across all measured parameters including peak current, voltage, and power. The device successfully completed repeated firing cycles, demonstrating that impedance-matched Marx generators maintain long operational lifetime exceeding 10,000 shots and high repetition rates greater than 0.1 hertz.

Magnetized Target Fusion and Supporting Innovations

TITAN’s power output is optimized for magnetized target fusion, a hybrid approach that combines elements of magnetic and inertial confinement. Unlike tokamaks, massive superconducting magnetic reactors that attempt to sustain fusion plasma for seconds or longer, MTF rapidly compresses plasma during microsecond-scale pulses, then releases it.

The confinement times in MTF systems are thousands of times shorter than tokamaks, occurring in milliseconds rather than seconds. This enables simplified magnetic field requirements and compact equipment footprints. Engineers only need to maintain plasma conditions briefly rather than stabilizing them for long durations.

A critical challenge in large-scale pulsed-power systems involves managing gas-switch reliability across hundreds or thousands of devices. Fuse solved this challenge with a novel air delivery system that independently controls pressure in each of TITAN’s 14 stages. This allowed pulse-shaping experiments with rising times of 83.6 ns (fast), 99.2 ns (standard), and 128.2 ns (slow).

TITAN’s impedance-matched design also delivers superior energy efficiency—about 90 percent energy transfer from capacitors to load—while the reduced operating voltage extends component life by orders of magnitude.

Scaling Path: From TITAN to Z-Star to Net Energy Gain

Fuse’s engineering roadmap leverages TITAN’s modular architecture to scale up. The planned Z-Star facility would connect 16 TITAN modules in parallel, generating ~15 terawatts—approaching the Sandia Z facility’s performance but with lower voltage, higher efficiency, and greater flexibility.

From Z-Star, the roadmap envisions full-scale demonstration facilities capable of achieving net energy gain, where output exceeds input. This staged approach—TITAN → Z-Star → net-energy-gain facility—offers a practical path forward, avoiding risky leaps that introduce untested variables.

Competition in the fusion sector is intensifying, with other startups such as Commonwealth Fusion Systems pushing tokamak-based systems. TITAN’s peer-reviewed publication marks the world’s first successful impedance-matched Marx generator demonstration of this scale, representing a major first-mover advantage.

Fuse also operates a revenue-generating radiation-effects testing business using TITAN’s output, serving semiconductor, satellite, and defense clients—providing steady income that reduces reliance on outside investment.

Fusion Potential, Remaining Challenges, and Outlook

If successful, TITAN-based fusion plants could provide virtually limitless, carbon-free energy. Hydrogen isotopes from seawater, minimal radioactive waste, extraordinary energy density, and zero emissions make fusion an ideal long-term energy solution.

Despite the breakthrough, challenges remain. Electromagnetic wave propagation in high-voltage stages requires further study, and scaling from six to fourteen stages introduces synchronization and impedance-matching complexities. Long-term firing reliability and integration with real fusion targets remain active research areas.

Fuse Energy Technologies’ TITAN device has shown that alternative fusion approaches can achieve groundbreaking performance outside traditional mega-lab environments. With peer-reviewed validation and a credible scaling roadmap, the company is positioned at the forefront of the push toward commercial fusion energy.

The coming years will determine whether TITAN’s architecture can move from laboratory success to practical, affordable, industrial-scale electricity generation—potentially marking one of the defining technological advances of the 21st century.