In an unexpected move, forklift giant Hyster-Yale announced the elimination of 575 jobs on November 19, 2025, marking a significant workforce reduction at its Cleveland headquarters. This decision has sent shockwaves through the manufacturing sector, raising urgent questions about the stability of U.S. manufacturing jobs.

With the company’s stock down approximately 43%, the layoffs have sparked concerns about both the company’s future and the broader industrial landscape. As competitors and analysts scramble for answers, the real impact of these cuts is still unfolding.

Escalating Losses

Hyster-Yale’s layoffs are part of a broader trend that’s also affecting Oregon, where approximately 9,400 manufacturing jobs have been lost over the past year. The company’s stock price has plummeted by approximately 43% in 2025, reflecting the uncertainty surrounding its ability to recover.

This steep drop signals wider issues in the industry and raises questions about the viability of companies that depend heavily on U.S. manufacturing. As investors grow more cautious, the fate of Hyster-Yale’s future becomes more uncertain.

Hyster-Yale’s Legacy

Founded in the early 20th century, Hyster-Yale has long been a dominant force in materials handling, with its forklifts powering supply chains across North America. The company has been a symbol of American manufacturing, weathering economic storms for decades.

However, as automation accelerates and competition becomes fiercer, Hyster-Yale now finds itself facing its most challenging period. Once a pillar of industrial success, it now risks falling behind without a clear strategy for adapting to the changing landscape.

Global Pressures Mount

The company is grappling with rising tariffs and global supply chain disruptions that are weighing heavily on its operations. In Q3 2025 alone, Hyster-Yale incurred $40 million in tariff-related costs, adding significant strain to its already stretched resources.

These financial pressures, combined with a 4% year-over-year drop in sales, have left the company with difficult choices. The increased cost of doing business is making it harder for manufacturers to stay afloat, and Hyster-Yale is no exception.

Largest Layoff in Company History

On November 19, 2025, Hyster-Yale confirmed the elimination of 575 jobs company-wide. This represents the company’s largest restructuring since becoming an independent public company in 2012, and the largest single workforce reduction during the current decade of operations. This represents a significant restructuring action affecting the company’s global operations, marking a substantial shift in the company’s approach to managing its workforce.

The company has emphasized that these layoffs are necessary for ensuring long-term stability. But the immediate impact on employees and their families is undeniable, and the question remains whether the company can recover from such a drastic measure.

Impact Beyond Ohio

The layoffs extend well beyond Ohio, affecting other key sites, including Oregon and North Carolina. At the Fairview site in Oregon, 37 workers lost their jobs, while in Pitt County, North Carolina, more than 100 employees were let go.

These cuts are not just statistics—they represent real people whose livelihoods are at stake. The layoffs have left many families in uncertainty, adding to the ripple effects felt across local communities that depend on these manufacturing jobs.

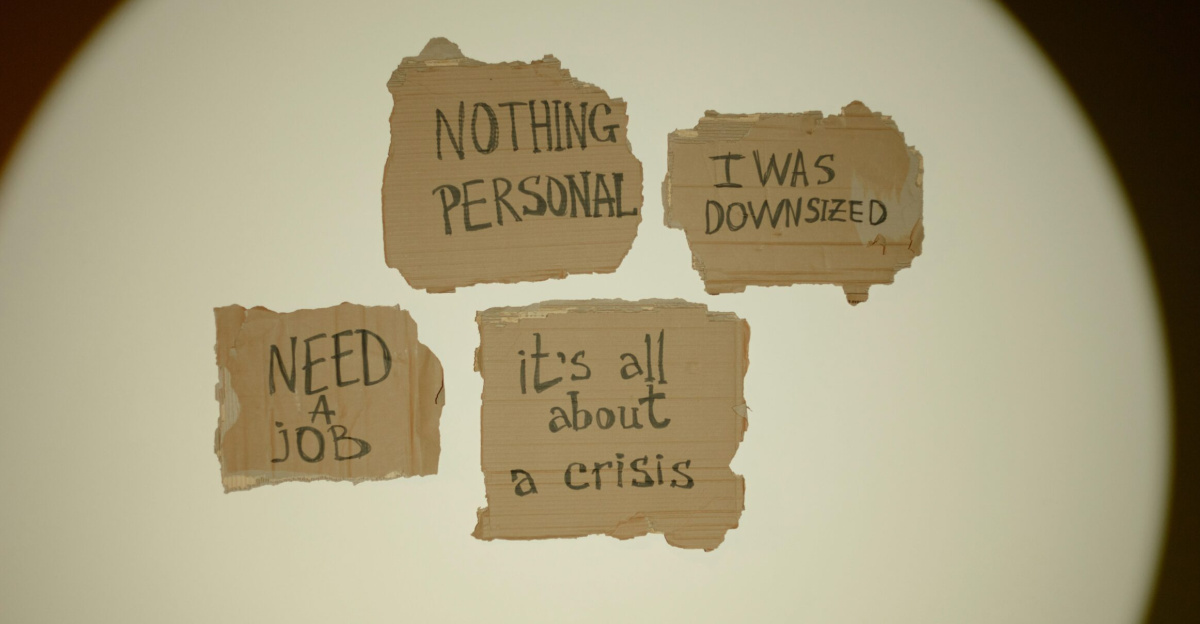

The Layoffs

The layoffs have created a wave of uncertainty and anxiety for workers. Many employees, who were told the cuts were necessary for long-term strength, now face an uncertain future. As one worker put it, “The impact of these decisions is deeply personal, and many of us are left in the dark.”

While the company claims that the workforce reduction is crucial for its survival, the emotional toll on affected employees is undeniable. The workers left behind are now questioning whether these tough decisions will truly secure the company’s future.

Competitors Feel the Squeeze

Hyster-Yale’s struggles are far from isolated. ThyssenKrupp, a major player in the industrial sector, has also announced plans to cut 5,000 jobs by 2030, citing overcapacity and global competition.

As global pressures mount, companies in the forklift and industrial sectors are being forced to make tough decisions. The entire industry is under pressure to either adapt or face the risk of shrinking, as they struggle to navigate the current economic climate.

Macro Trends

The layoffs at Hyster-Yale reflect broader challenges facing U.S. manufacturing. The sector is still reeling from the disruptions caused by the COVID-19 pandemic, with foreign competition and automation accelerating job losses.

Oregon’s manufacturing unemployment rate now hovers near 5%, reflecting the challenges workers face in finding new jobs. The current situation mirrors the darkest days of the Great Recession, highlighting just how difficult it is for the sector to recover.

Tariff Costs Shock the System

One of the most significant contributors to Hyster-Yale’s woes is the $40 million in tariff costs the company incurred in just one quarter. These added expenses have severely impacted its financial standing, further complicating its efforts to turn a profit.

With these costs mounting, Hyster-Yale was left with no choice but to take drastic action. The question remains: What other manufacturers are silently struggling under the weight of similar tariff burdens?

Internal Strain

Within Hyster-Yale, the atmosphere is tense as employees and managers face mounting pressure. The company is under intense scrutiny as it attempts to navigate financial losses, shrinking markets, and difficult decisions about its future.

With profitability in question, the company’s leadership is grappling with the weight of the workforce cuts and the task of finding ways to bring the company back to financial stability. The strain is evident, and the path forward remains unclear.

Leadership’s Tough Decisions

Hyster-Yale’s leadership team, led by Executive Chairman Alfred M. Rankin Jr., has emphasized that these decisions are “difficult but necessary” for ensuring long-term viability. As the company struggles to turn things around, the board continues to review strategic options, including potential restructuring.

But the company’s future depends on more than just cost-cutting measures. The real question is whether Hyster-Yale can adapt quickly enough to remain competitive in an increasingly complex global market.

Looking to the Future

Despite these setbacks, Hyster-Yale isn’t standing still. The company is investing in automation and digital transformation to improve efficiency and stay competitive. These measures are expected to help the company recover by mid-2026.

But with increasing competition and a shrinking market, the question remains: Can these efforts be enough to position Hyster-Yale for a successful rebound, or will the company be left behind?

Expert Outlook

Industry analysts are cautiously optimistic but acknowledge the ongoing challenges faced by Hyster-Yale. While some see a potential recovery if global trade stabilizes, others warn that continued tariff pressures and weak demand could prolong the downturn.

As the company looks to the future, it’s unclear whether its efforts will be enough to restore profitability. Industry experts believe that Hyster-Yale’s next steps will be crucial in determining its long-term success.

What’s Next for Hyster-Yale?

Looking ahead, Hyster-Yale faces a tough road to recovery. While the company is streamlining operations to reduce costs, it remains to be seen if these measures will be enough to restore profitability.

The big question is whether the company can continue to adapt to the changing global market and survive in an era where manufacturing jobs are increasingly at risk.

Policy Implications

The ongoing wave of manufacturing layoffs has prompted policymakers to take action. At both the state and federal levels, there are discussions about how to support displaced workers and strengthen U.S. manufacturing against foreign competition and tariff shocks.

As the government debates the best course of action, the fate of thousands of displaced workers remains uncertain. It’s clear that something needs to change to address the mounting challenges facing the manufacturing sector.

International Impact

Hyster-Yale’s struggles are not unique to the U.S. European manufacturers like ThyssenKrupp are also cutting jobs, underscoring the global nature of the crisis. The interconnectedness of supply chains means that the impact of these layoffs is felt across the world.

This situation highlights the fragility of global manufacturing and the challenges faced by companies attempting to stay afloat amidst rising costs and economic uncertainty.

Legal and Environmental Considerations

As the number of layoffs increases, legal concerns over severance packages and worker protections are becoming more prominent. In addition, some advocates believe that restructuring could lead to greener, more sustainable manufacturing practices in the long term.

The pressure on Hyster-Yale to make ethical and sustainable decisions is mounting, and how the company handles this will shape its reputation moving forward.

Cultural Shifts

The perception of manufacturing as a stable career is shifting. With automation accelerating and global competition intensifying, younger generations are increasingly wary of entering industries vulnerable to such disruptions.

This shift in attitudes has prompted calls for new training programs and educational pathways to ensure the workforce is prepared for the future of manufacturing.

Why It Matters

The layoffs at Hyster-Yale are a microcosm of the challenges facing the U.S. manufacturing sector. As the industry continues to adapt to global pressures, the future of workers and industrial communities hangs in the balance.

The decisions made today will shape the future of American manufacturing for years to come.