Ford’s Louisville Assembly Plant shuts its doors in December 2025, as 2,000 workers are laid off in the wake of a massive shift in production. The news hits hard: no pay for at least 10 months, as the plant retools to produce electric vehicles using Tesla-style Gigapress technology.

The automaker’s bold plan to make EVs affordable seems promising, but for these workers, the future is uncertain. Will they survive the long wait for jobs that may not materialize as promised? Stay tuned for the dramatic impact of Ford’s gamble on its workers and Kentucky’s economy.

The Shift to Electric: Ford’s Bold Move

Ford is pivoting to Tesla-style manufacturing with a focus on electric vehicles. The Louisville plant will be retooled to adopt Gigapress technology, which will drastically reduce production costs.

CEO Jim Farley describes this as a “Model T moment,” reminiscent of Henry Ford’s original push to make cars affordable for workers, though this shift comes with a heavy cost for employees.

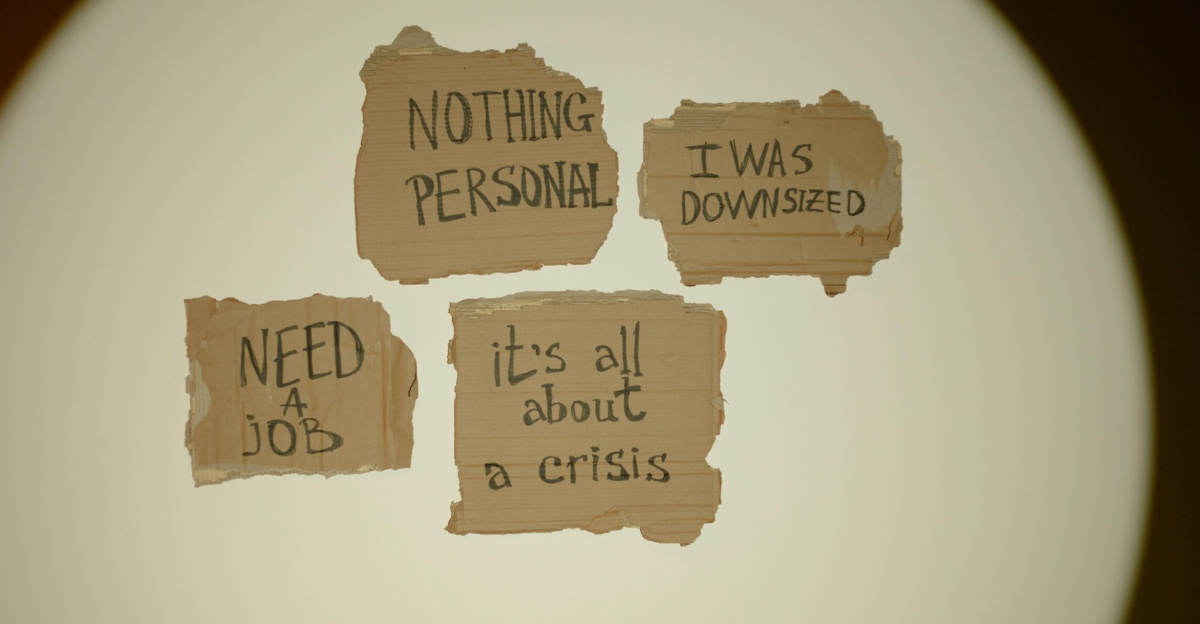

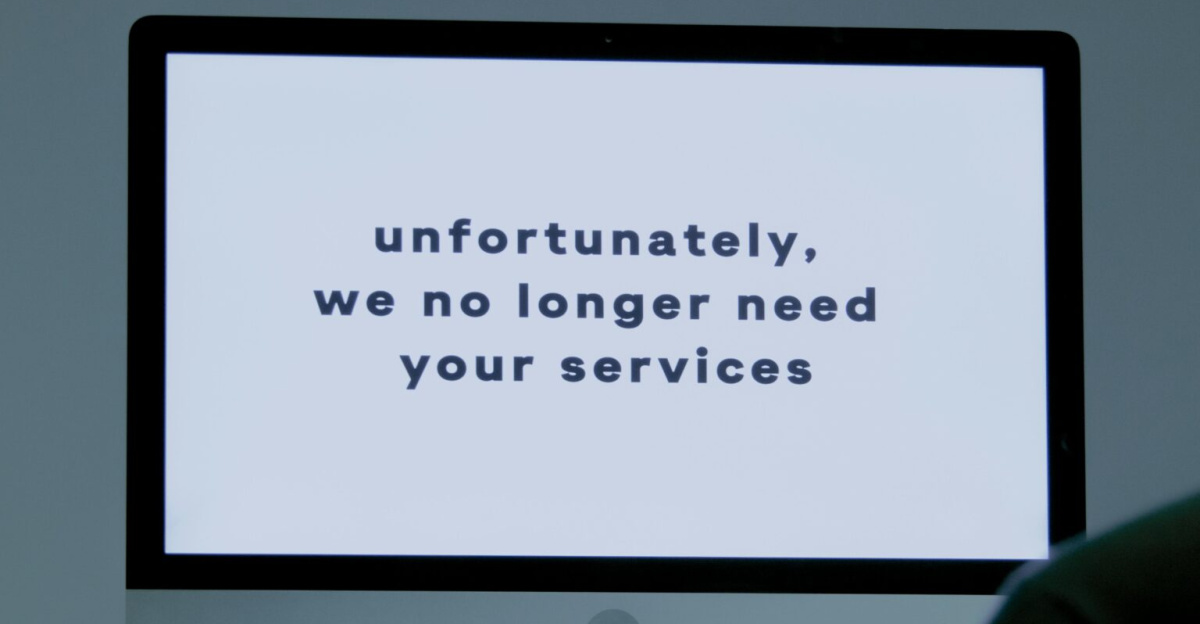

Financial Impact on Workers

2,000 workers will face a loss of income for at least 10 months, starting in December 2025. For the first four months, they’ll receive enhanced unemployment benefits, but after that, their income will drop drastically, leaving many to navigate significant financial hardship.

Some workers may never return due to permanent job cuts expected once the retooling is complete in 2027.

Retooling for the Future

Ford is investing in advanced automation to streamline the production of a new $30,000 electric pickup truck. This move reflects Ford’s commitment to competing in the growing EV market.

However, it comes with a cost: the plant’s workforce will shrink as automation takes over, leaving fewer jobs for the same level of production.

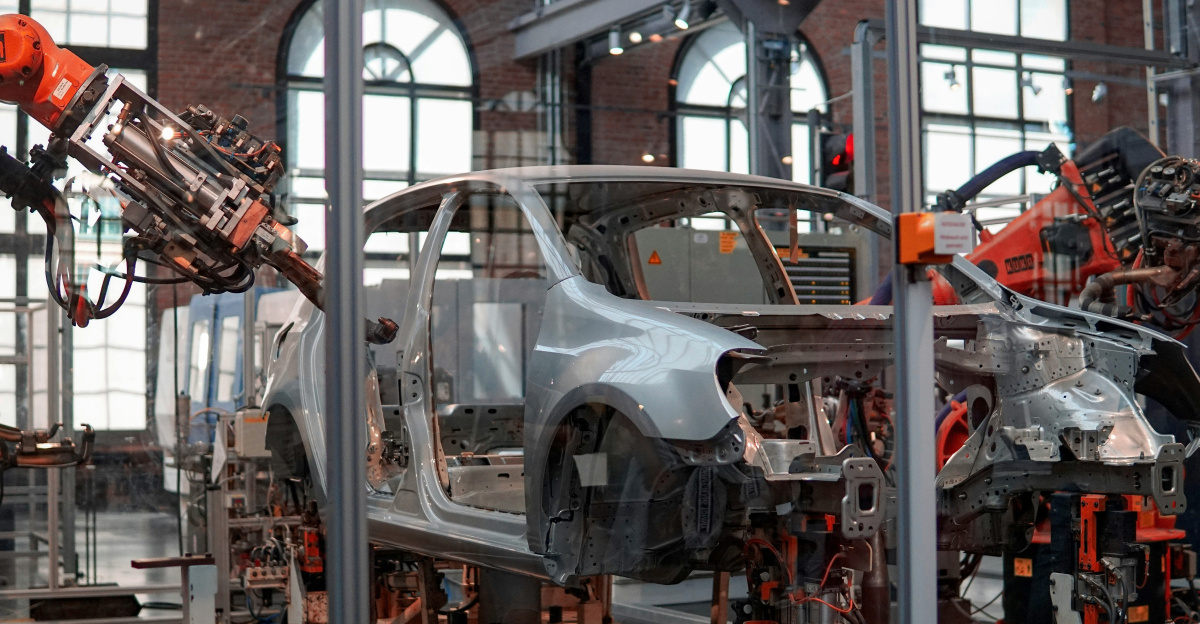

A New Era in Manufacturing

The switch to Tesla-style Gigapress technology means Ford is betting on a future where fewer workers are needed.

This technology, which allows for large-scale stamping of EV parts, will reduce the plant’s parts count by 20% and fasteners by 25%. While it’s a leap forward in manufacturing efficiency, it also means fewer jobs for the workers it displaces.

Local Economic Impact

Kentucky’s economy will take a significant hit due to these layoffs. The local community will experience reduced spending as the laid-off workers face financial uncertainty.

With a projected $120 million loss in wages, the ripple effect will be felt across businesses that rely on the disposable income of Ford employees, from retailers to service providers.

The Role of UAW Local 862

The United Auto Workers (UAW) Local 862, which represents the affected Ford employees, is working to secure benefits for workers during the shutdown.

Union president Todd Dunn and benefits rep Jim Fisher are negotiating with Ford to ensure workers are compensated and supported throughout this transition period. However, union leaders also advise workers to seek other employment during the shutdown.

Potential for Job Absorption in Louisville

The sudden influx of 2,000 skilled workers into the job market in Louisville presents challenges for the local economy.

The city has only about 10 to 15 automotive manufacturing facilities, and this layoff represents a temporary labor surplus that could lead to wage suppression in the sector, making it harder for workers to find comparable employment.

Political Fallout

Kentucky Governor Andy Beshear has expressed support for Ford’s transition, framing it as a commitment to the state’s manufacturing future.

However, local politicians and union leaders are pushing for more support for displaced workers. The challenge lies in balancing the long-term economic benefits of automation with the immediate pain felt by thousands of workers and their families.

Impact on Suppliers and Subcontractors

Ford’s decision to shift to electric vehicle production will also affect its suppliers. While some parts suppliers may face reduced demand for traditional components, those supplying EV-specific parts may see increased opportunities.

However, this transition comes with uncertainty, as many of the changes will depend on the successful ramp-up of the new manufacturing process.

Broader Global Supply Chain Implications

Ford’s move reflects broader trends in the automotive industry, where companies are adopting automation and moving toward electrification.

This shift is part of a global effort to localize production and reduce reliance on international supply chains. It also positions Ford to better compete with other automakers, like Tesla and BYD, in the fast-growing EV market.

Mental Health and Community Stress

The layoff will take a toll on workers’ mental health and well-being. Facing months of financial instability, many workers will experience increased stress, anxiety, and uncertainty.

Local healthcare providers and community organizations are preparing for an uptick in demand for mental health services and support during this challenging time.

The Environmental Argument

Ford’s push to electrify its lineup and adopt more sustainable production methods offers long-term benefits for the environment.

With fewer parts needed for the new EV platform, Ford hopes to reduce waste and increase efficiency. This is a step forward in Ford’s commitment to sustainability, but it comes at a human cost for the workers involved in the transition.

Automation and Its Discontents

The debate around automation and job displacement is intensifying. While Ford’s move towards automation could make vehicles more affordable and competitive, it also raises concerns about job security.

Critics argue that automation should be balanced with efforts to protect workers, ensuring that they aren’t left behind in the transition to a more technologically advanced manufacturing process.

UAW’s Response to Automation

Union leaders have expressed frustration with Ford’s decision to embrace automation, which they argue replaces workers without offering sufficient support.

While the union has secured benefits for workers during the shutdown, they are pushing for retraining programs to help workers transition into new roles in the changing automotive landscape.

The Race Against Chinese EVs

Ford’s $30,000 electric truck aims to compete in a market already flooded with affordable Chinese-made EVs.

Companies like BYD are already producing electric vehicles at a fraction of the cost, raising questions about whether Ford’s strategy will succeed. If Ford cannot deliver on its promises, it risks falling behind in a rapidly evolving market.

Investor Concerns

Investors are closely watching Ford’s transition to EV production. The company is betting heavily on the success of its $30,000 electric pickup truck, but any setbacks in the retooling process could lead to stock volatility.

Investors are questioning whether Ford can pull off this ambitious plan and generate the expected returns on its massive investment.

Ford’s Long-Term Strategy

Ford’s long-term strategy hinges on the success of its retooled Louisville plant and the successful launch of its new electric truck in 2027.

The company’s ability to navigate the challenges of automation, EV production, and market acceptance will determine whether the plan succeeds or fails. The next few years will be crucial for the company’s future.

Kentucky’s Economic Future

Kentucky’s economy will need to adapt to the changing landscape of manufacturing. The state is hoping to attract new industries and workers, but the short-term fallout from the Ford layoffs will be significant.

Local governments will need to provide support and retraining programs for affected workers to help them transition into new roles.

The Bigger Picture

Ford’s retooling of its Louisville plant represents a significant shift in U.S. manufacturing, with automation and electrification reshaping the landscape.

While the long-term benefits of this transformation may be substantial, the immediate impact on workers and communities is undeniable. As the industry moves forward, it will be crucial to ensure that workers aren’t left behind in the transition.