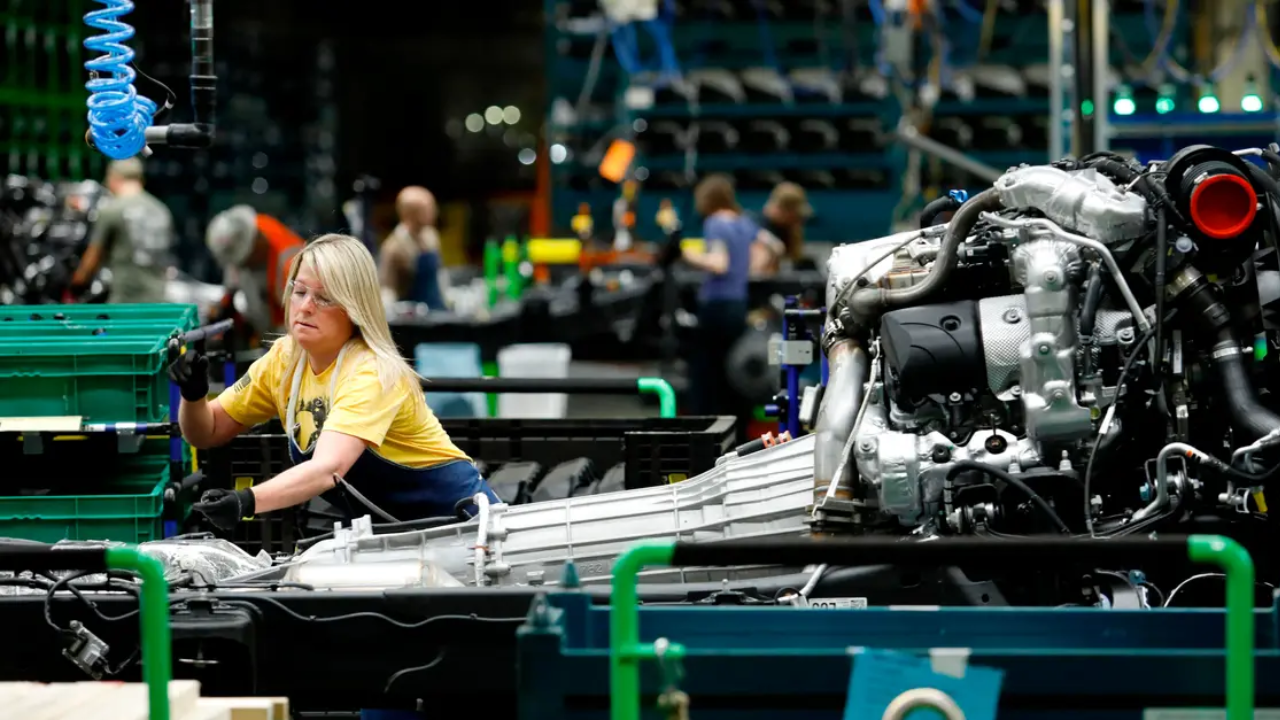

Between July and October 2025, Michigan’s automotive sector experienced a significant wave of layoff announcements as five major suppliers filed WARN notices for job cuts affecting 427 workers, with layoffs beginning in October. The closures—spanning companies like Dana Thermal Products, NPR of America, and DP World Logistics—have raised concerns among communities reliant on the auto sector. The announcements have left families, local businesses, and industry leaders grappling with the question: what triggered this contraction, and what does it mean for Michigan’s future?

Business Downturns and Facility Closures

The primary driver behind these layoffs is a sharp decline in business, particularly in the electric vehicle (EV) segment. Dana Thermal Products, for example, cited low EV demand as a key reason for shuttering its Auburn Hills plant, which laid off 200 workers beginning in October 2025. Akebono Brake Corp. pointed to a broader downturn in U.S. operations when announcing the layoff of 48 employees at its Farmington Hills facility. DP World Logistics was forced to close its Warren location, affecting 70 workers, after losing its only customer. NPR of America filed a WARN notice in August 2025 to close its Grand Haven facility, with 64 layoffs occurring between October 2025 and February 2027. Davalor Mold Company also announced the closure of its New Baltimore facility, affecting 45 workers. These moves reflect a strategic retrenchment as companies seek to stem losses by trimming unprofitable operations.

Industry experts note that such closures are not isolated incidents but part of a larger trend. The auto supply chain is under immense pressure as consumer preferences shift and global competition intensifies. Suppliers are being forced to adapt quickly, and unfortunately, that often means job losses and facility closures.

Additional Industry Pressures

Beyond the five supplier closures, the International Automotive Components Group announced permanent layoffs of 178 workers at its Mendon plant and additional cuts at its Alma facility, totaling 246 workers, due to Ford phasing out certain vehicle models. General Motors also announced significant EV-related layoffs in Michigan and Ohio in October 2025, citing regulatory changes and slower EV demand. These developments underscore the broader challenges facing Michigan’s automotive manufacturing sector.

Supply Chain Disruptions and Industry Transitions

Michigan’s auto suppliers are critical links in a global supply chain. The transition to electric vehicles has created significant pressure on traditional suppliers, as evidenced by the closures and restructuring across the state. Federal EV tax credits expired on September 30, 2025, potentially impacting consumer demand.

This pattern mirrors challenges seen in other auto manufacturing regions worldwide. In Germany, for example, suppliers have faced similar pressures as the industry transitions to electric vehicles, leading to widespread restructuring and job cuts. Companies like Bosch have announced thousands of job reductions as part of their EV transition strategy. The global nature of these disruptions underscores the interconnectedness of the automotive sector and the far-reaching consequences of industry transitions.

Workers and Communities Face Uncertainty

Behind the statistics are real people facing uncertain futures. For many families, the loss of a steady paycheck means difficult choices about housing, healthcare, and education. Workers who have spent years or decades in the auto parts industry now face the challenge of finding new employment opportunities.

Looking Ahead: Uncertainty and Opportunity

The wave of layoffs has reignited debates about the future of Michigan’s auto industry. Some advocate for greater investment in green technology and electric vehicles, while others stress the importance of preserving manufacturing jobs. The state’s cultural identity as the heart of American auto manufacturing faces a pivotal moment.

As Michigan navigates this period of uncertainty, resilience and adaptation will be key. The coming months will test the industry’s ability to respond to shifting market demands and technological change. For workers, families, and communities, the stakes are high—but so too is the potential for renewal and growth if new opportunities can be seized.