Chinese researchers at Tianjin University recently announced a breakthrough lithium‑metal battery reaching an unprecedented energy density of over 600 Wh/kg.

Media hailed this as a “battery revolution,” hinting at game-changing range improvements for EVs, drones and more.

Such a cell packs roughly twice the energy of today’s best batteries. Yet experts caution that translating this lab result into cars and planes will take years.

The Nature paper underscores scientific progress, but the path to real products is still complex. This report examines the promise and the hurdles ahead.

Energy Density

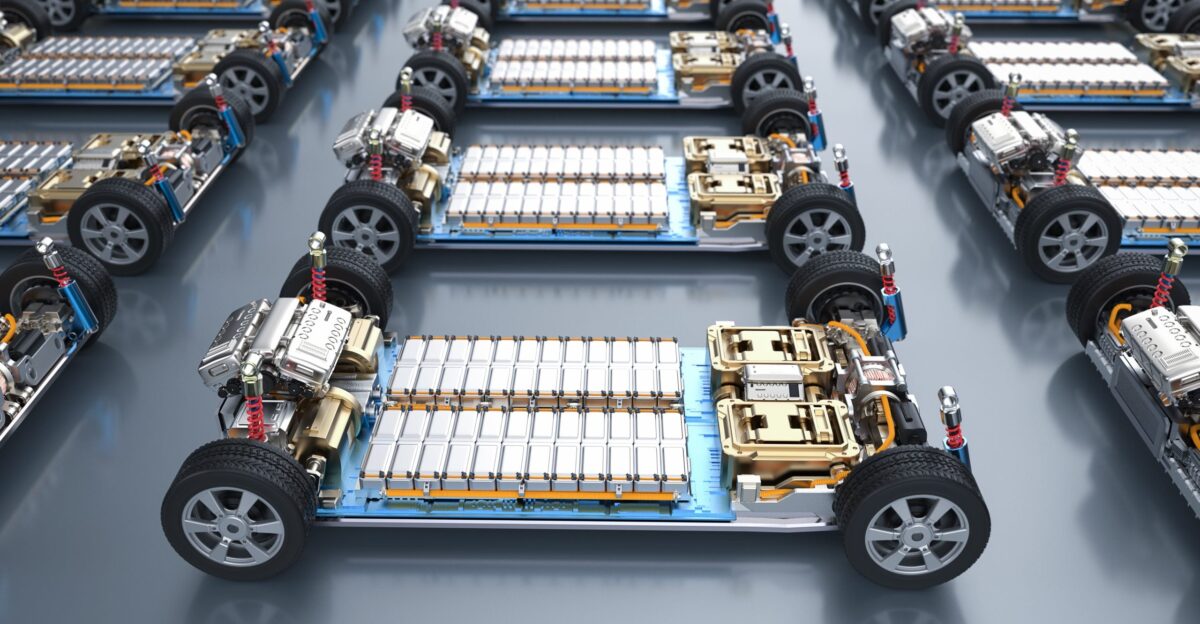

Energy density (Wh/kg) measures how much energy a battery stores per unit weight. Today’s commercial EV cells typically reach only about 150–300 Wh/kg. That limitation means current batteries add hundreds of pounds and limit driving range.

In response, global researchers and automakers are pouring billions into boosting energy density. Higher density could enable lighter vehicles or a far longer range.

But pushing it up involves tough tradeoffs: stability, life span, cost and safety can all suffer.

Understanding the new Tianjin cell requires first grasping why Wh/kg is the key metric driving this multibillion‑dollar race.

Tesla’s Leadership

Tesla pioneered new battery designs to raise energy density and cut costs. Its large 4680 cylindrical cell (46 mm × 80 mm) already scores around 272–296 Wh/kg, among the best commercially.

These cells are now used in Tesla’s flagship models – initially in a Texas-made Model Y and in the Cybertruck – aiming for longer range and faster charging. Tesla invested heavily to scale 4680 production at Gigafactories.

By comparison, the Tianjin result (600 Wh/kg) would be roughly double that density.

Tesla’s data reminds us that going from 270 Wh/kg to 300 Wh/kg was already a multi‑year effort.

Industry Context

Competition is fierce. In 2022, China’s CATL unveiled its “Qilin” pack, reaching 255 Wh/kg – a record at the time, and BYD’s popular Blade battery (LFP chemistry) manages around 150 Wh/kg.

Electric vehicle makers like Volkswagen, GM and startups are all pushing new chemistries (silicon anodes, solid-state electrolytes, sodium-ion) to break above 300 Wh/kg.

Every few Wh/kg of extra density translates into real range gains or weight savings.

The Tianjin announcement, therefore, rattles global industry: if true, it upends the benchmarks set by Tesla, CATL and others.

Nature Breakthrough

On Aug. 13, 2025, the Tianjin team published in Nature that they built lithium-metal pouch cells hitting 604.2 Wh/kg and 618.2 Wh/kg (for two designs) – roughly twice Tesla’s best. This result comes from a novel “delocalized electrolyte” that rearranges how lithium ions move.

The People’s Daily Xinhua summary calls it a 200–300% jump in both energy and endurance.

One battery can now store about 2× the energy for a given weight, or be 2× lighter for the same capacity. Here’s where it gets interesting: the researchers used AI to screen thousands of solvent/salt combinations, finding a mix that let lithium ions flow more freely (the “disordered solvation microenvironment”).

The achievement shatters previous lab records. But as we’ll see, this double-density cell has a catch.

Pack Performance

The team then built a complete battery pack (multiple cells) and measured 480.9 Wh/kg at the pack level. That packs energy like a tank of gas for much less weight – roughly 200–300% above today’s Li-ion packs.

Such a pack, if real, could enable EVs with ~600‑mile range on a single charge or aircraft powered by all-electric cells. State media noted the “Pack480” prototype confirms the concept might scale beyond a single cell.

Still, these are lab demos. In tests, the pack could only be charged/discharged 25 times before degrading.

In other words, the prototype litters the performance table – amazing energy per pound, but only about 1‑2 dozen full cycles so far. The next questions are life and safety.

Researcher Perspective

Professor Hu Wenbin (lead of the project) is cautiously optimistic. He emphasizes this is mainly a lab demo for now. “We have established a pilot production line for high-energy lithium-metal batteries and successfully implemented this innovative technology in three models of domestically developed micro unmanned aerial vehicles,” Hu said.

In other words, they’re already using the cells in drones, where weight is king and cycle needs are low.

Hu notes the core was years of R&D: “Our delocalized electrolyte design fosters a more disordered solvation microenvironment,” he explains, which balances the usual electrolyte chemistry constraints.

That means lithium ions can deliver energy far more efficiently inside the cell. The work is primarily science at this stage, targeted at “Battery600” and “Pack480” prototypes, not a ready-for-market car battery.

Pilot Production

Despite being early, the team has moved beyond just a lab bench. They built a pilot production line to make these high-energy cells. Those batteries were quickly put into service in three types of domestic drone platforms.

In flight tests, the new cells allowed drones to stay aloft roughly 2.8 times longer than previous batteries.

This dramatic endurance leap validates the density gains in a real application. (One drone pilot remarked it felt like “nearly tripling our flight range” — far more than anyone expected.)

However, the lab pack’s longevity was still limited: after only 25 charge cycles tests showed notable wear.

Market Implications

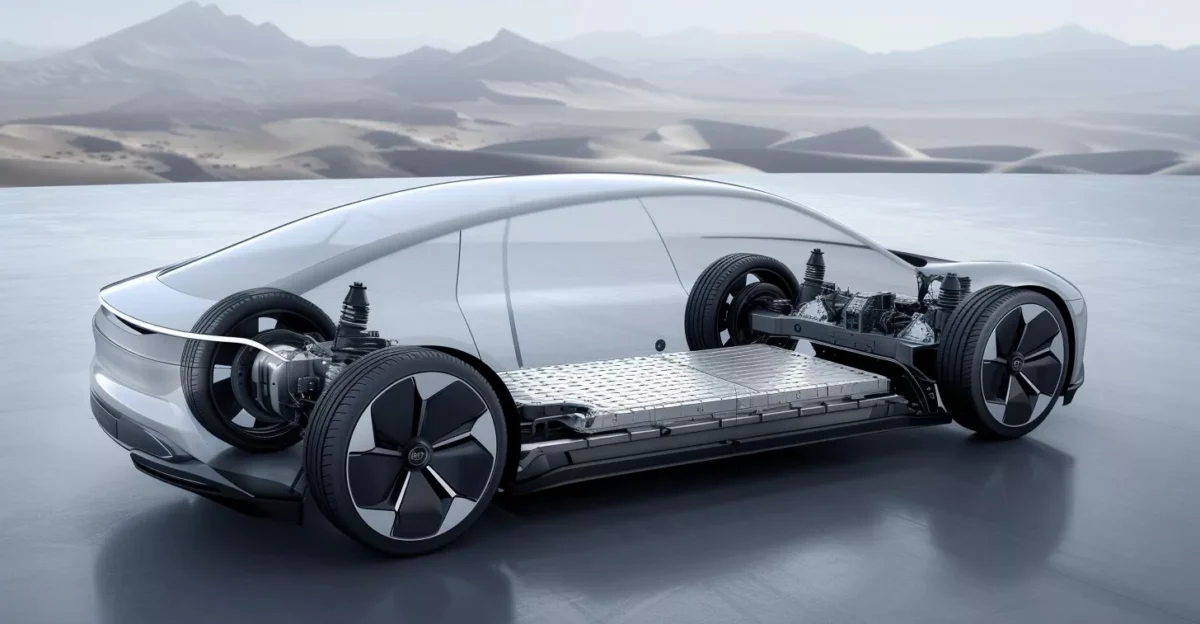

If Tianjin’s results can be refined, the EV market would be transformed. Doubling energy density means a typical electric car battery pack could either be half the weight or carry twice the range.

Analysts immediately noted this would “shatter range anxiety” – theoretically giving 600‑mile EVs or vastly lighter aircraft batteries.

Automotive designers could ditch thousands of pounds of battery, dramatically speeding up and lightening vehicles. Even mainstream drivers perk up at the idea: a farmer hauling goods or a family on a road trip might only recharge monthly.

Meanwhile, performance EVs could hit 0–60 in seconds with easier energy reserves. Basically, almost any electric mobile application – from cars to flying taxis – could be reimagined if pack-level density really jumps this high.

Critical Limitation

However, there is a stark reality check: cycle life. The high-density Tianjin cells faded after only about 90–100 full charge cycles. At the pack level they tested, durability was worse – roughly 25 cycles.

By contrast, EV makers design batteries to last 1,000–1,500 cycles with at least 80% capacity (to meet 8–10 year warranty laws). A former battery R&D engineer explains bluntly, “No one buys a car battery that needs replacement in months.”

Even if an EV gained twice the range, most consumers (and companies) won’t accept a battery that loses half its capacity in a few dozen uses.

This life-expectancy gap is the biggest barrier to adopting such cells in cars or commercial products.

Industry Standards

Market and legal expectations underscore the gap. Today’s EV batteries are warranted to 8 years or ~100,000 miles, meaning about 1,000 charge cycles with minimal degradation. (Most Li-ion chemistries aim to maintain ≥80% capacity at that point.)

Tesla, for example, designs cells to handle thousands of cycles, and regulatory agencies enforce warranties in that range.

The Tianjin cells – 90 cycles to failure – fall dramatically short of even the lowest end of these benchmarks. Bridging this gap means either new chemistries or hybrid designs (like solid-state) that can marry energy density with longevity.

Until then, commercializing the “Battery600” for a car remains a distant goal.

Safety Challenges

Lithium metal anodes introduce extra hazards. Unprotected lithium reacts violently with air and moisture, and dendrite growth (spiky lithium deposits) can cause internal short circuits.

In many Li-metal cells, just a nail puncture or overheating can lead to fires or explosions.

The Tianjin design uses fluorine additives and special materials to mitigate this – indeed, the researchers report the battery survived open‑flame and cold tests.

But extensive automotive crash and abuse testing will be needed. In normal Li‑ion car batteries, inert electrolyte and safety circuits help prevent such failures. Until Tianjin’s cells are proven in thousands of abuse cycles and crash simulations, automakers will be cautious. Safety validation is as critical as energy density for any road‑going battery.

Research Strategy

The breakthrough was no accident – it came from targeted research strategies. The team used AI-driven materials screening to speed up electrolyte development.

By computationally testing hundreds of lithium salts and solvents, they identified a unique mixture of multiple salts/solvents that breaks the usual solvation rules. Partners at the National University of Singapore and industry labs contributed knowledge and equipment.

The result – what they call a “delocalized electrolyte” – effectively balances solvent-dominated and anion-dominated regions, allowing much more lithium storage.

This collaborative, AI-accelerated approach compressed what normally takes years of trial-and-error into months.

Expert Analysis

Battery experts applaud the density feat, but almost all immediately cite the cycle issue. Dr. Alice Chen, a materials scientist, comments that 600 Wh/kg “demonstrates what’s possible in theory” but notes “we can’t compromise the lifespan.”

Industry analysts point out that no one has yet combined ultrahigh density with 1,000+ cycles. As one veteran observer put it, “This is proof-of-concept science – very exciting for drones and defense, where fewer cycles can be tolerated.

For consumer EVs, it’s a long road.” Many believe the near-term winners will be applications where weight really matters (electric aircraft, UAVs, rockets) and batteries can be swapped or replaced quickly.

Meanwhile, solid-state and silicon anode research, which promise mid-range gains with good durability, remain high priorities for mass markets.

Future Outlook

In summary, the Tianjin result is a major scientific milestone. It shows that 600 Wh/kg cells are physically achievable, breaking the old “theoretical” ceiling. But it also confirms that turning this into a road‑ready battery will take further breakthroughs.

Researchers expect 2–5 years of work to improve the cycle life (and pack assembly) before seeing an actual EV on the road. Defense and aerospace sectors may see benefits sooner, where a shorter-lived but energy‑rich battery is acceptable.

In the civilian sector, expect incremental adoption: gradually the chemistry and engineering will evolve.

The broad takeaway: energy density limits are being redefined, but balancing density with durability and safety remains the field’s next big challenge.

Geopolitical Impact

China’s lead in battery innovation is bolstered by breakthroughs like this. The country already dominates global lithium processing, cell manufacturing and EV production. Achievements such as the Tianjin battery strengthen China’s hand in the clean energy transition, potentially giving Chinese firms a technology edge.

This in turn pressures U.S. and European companies to ramp up funding and research into next-gen batteries.

Policymakers have noted that “energy storage is a new battleground” and may institute incentives or regulations accordingly.

Every step forward in batteries is now a matter of national strategy. The West cannot afford to fall behind, lest it lose jobs and influence in the future automotive and aerospace industries.

International Response

Worldwide, battery makers are doubling down on their own approaches. Tesla and partners like Panasonic continue improving cylindrical and prismatic cells, and are also exploring solid-state cells for denser, safer batteries.

European firms (VW, Northvolt) and others pursue silicon-dominant anodes and sodium-ion technology as parallel paths.

The Tianjin breakthrough has injected urgency: executives at rival firms have openly said it highlights the need to diversify beyond incumbent technologies. Supply chain security also gets spotlighted – ensuring access to lithium, nickel, cobalt and advanced materials is now considered as strategic as oil was for the 20th century.

Some companies are relocating factories or forming new mining partnerships to reduce reliance on any single country’s supply.

Environmental Considerations

Higher energy density can shrink the environmental footprint of EVs. A 2× density means half the battery mass for the same range, cutting the ore mining, energy and materials needed per car.

Fewer raw materials per unit of storage is a clear green benefit. However, lithium‑metal batteries may require new recycling methods. For instance, lithium salts like LiFSI and fluorinated additives aren’t present in current battery recycling streams.

Experts warn that the industry must adapt processes now or risk waste issues. Life-cycle studies are just starting to include these chemistries.

The net impact is promising (lighter, more efficient cars), but lifecycle analysis and recycling must be planned in parallel.

Consumer Expectations

News of a 600 Wh/kg battery inevitably raises consumer hopes for “next-gen” EVs. Many drivers already expect 500‑mile ranges from upcoming models. The Tianjin claims may fuel unrealistic timelines – not every breakthrough hits the road soon.

Market analysts urge companies to temper expectations: range gains will come gradually. Surveys show drivers care as much about fast charging and reliability as raw range.

As one EV owner said, “I’m excited by the science, but I’ll be happy if charging stops at 15 minutes and the battery lasts 15 years.” Education and communication will be key.

Customers will see incremental range boosts and battery warranties stay solid; the “fully 600-mile” EV will likely wait for further R&D before delivery.

Innovation Signal

Regardless, the Tianjin result sends a clear signal: battery innovation is advancing at breakneck speed. Achieving 600 Wh/kg proves that previous limits were technological, not fundamental. As Interesting Engineering notes, researchers have “cracked a long-standing barrier” in lithium battery chemistry.

This encourages a new wave of creativity: scientists worldwide will seek ways to combine such high densities with longevity.

The next challenge is balancing these factors – the priority now is to boost cycle life without sacrificing the newfound energy per weight.

This milestone is both an endpoint and a starting line: it shows the journey is possible, and the next leaps will focus on making high-energy batteries also last long and remain safe for all applications.