General Motors will temporarily halt production at its Wentzville, Missouri assembly plant from September 29 to October 19, 2025, affecting the production of Chevrolet Colorado and GMC Canyon trucks, as well as Express and Savana vans.

This decision, driven by ongoing supply chain issues, raises concerns about manufacturing stability and will result in temporary layoffs for nearly 4,000 workers.

Jobs on the Line

The recent three-week shutdown of the GM plant in Wentzville poses a serious threat to the livelihoods of thousands of employees and their families, highlighting the vulnerability of auto sector jobs to global supply chain disruptions.

This temporary closure serves as a significant indicator of broader challenges facing the automotive manufacturing industry.

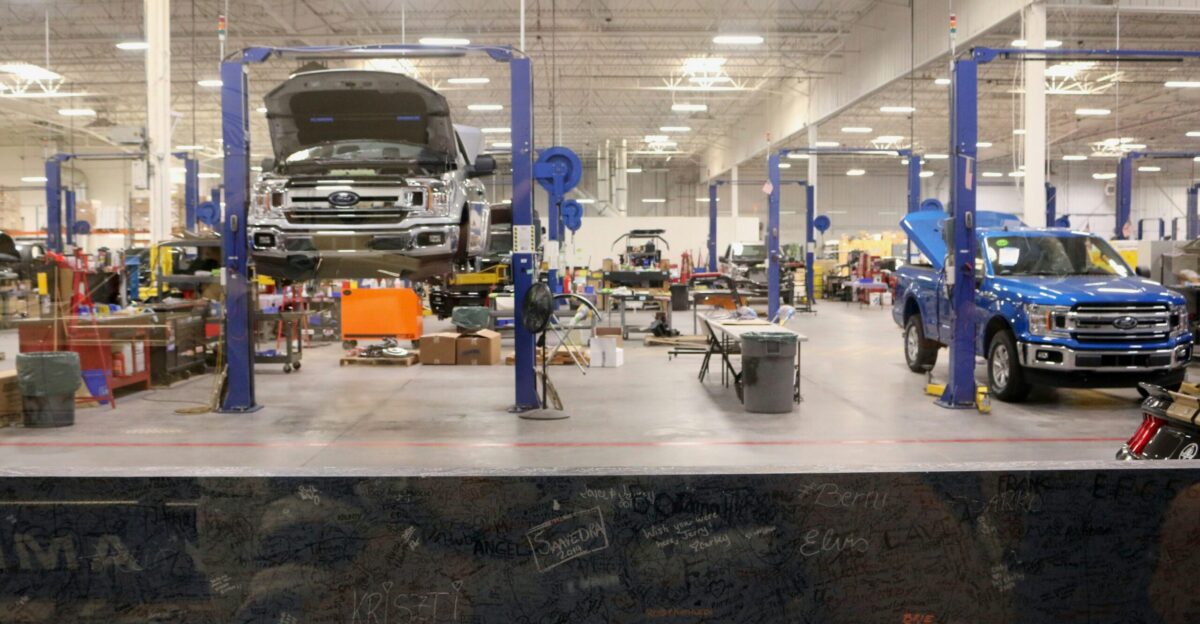

Wentzville’s Role

The Wentzville Assembly plant is vital to General Motors’ U.S. operations, producing full-size commercial vans and midsize pickup trucks for various markets. Its consistent output is critical for commercial fleets, small businesses, and consumers nationwide.

Disruptions at this key facility can significantly impact the automotive supply chain and the availability of commercial vehicles.

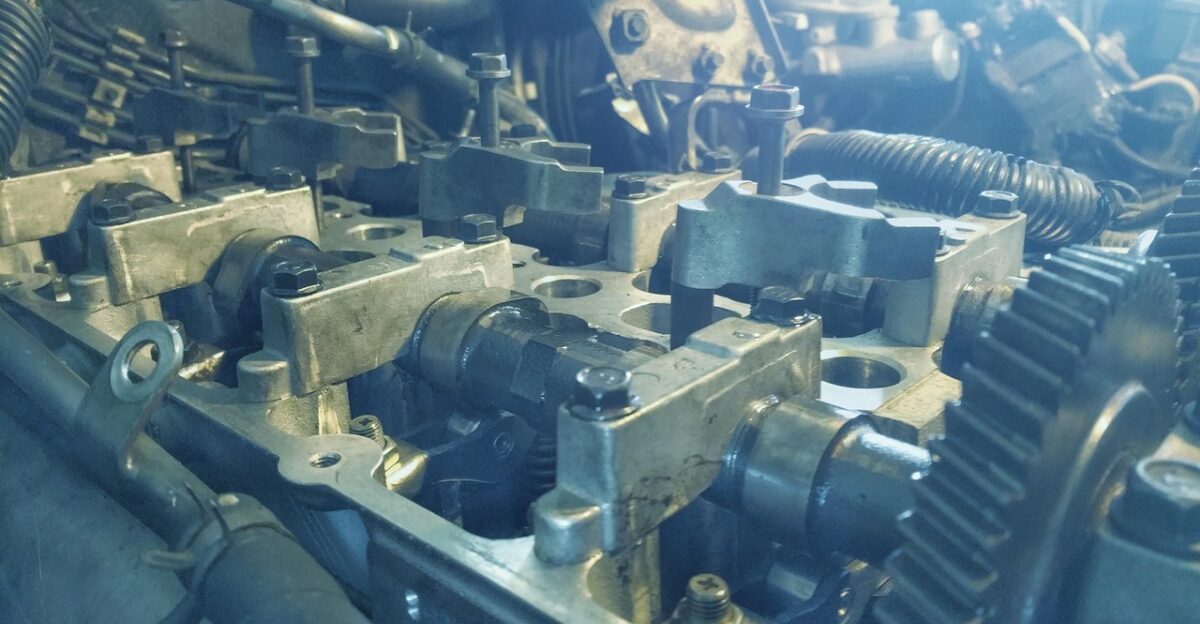

Mounting Supply Strains

The automotive industry has faced major supply chain issues in recent years, including semiconductor shortages, labor strikes, and logistical delays.

The recent parts shortage at Wentzville underscores a broader trend affecting the sector, as suppliers struggle to keep up with fluctuating demand and navigate complex international logistics.

Shutdown Announced

On September 12, 2025, General Motors announced a temporary shutdown of the Wentzville plant from September 29 to October 19, 2025, due to a critical parts shortage.

Most production shifts will be halted, with operations expected to resume on October 20, depending on supply recovery.

Regional Impact

The three-week closure is likely to significantly impact Missouri’s local economy.

Wentzville’s assembly plant is a major employer, and the loss of wages for nearly 4,000 workers will affect surrounding businesses, local services, restaurants, and retail establishments, impacting the broader community.

Workers in Limbo

Union representatives have acknowledged the strain and uncertainty affecting employees during the current situation. Many are facing weeks without steady work and income.

UAW Local 2250 leaders expressed gratitude for members’ understanding and flexibility during this challenging time, as workers and their families prepare for potential financial instability and personal disruptions ahead.

Competitors Watch Closely

Automakers and industry stakeholders are closely monitoring the Wentzville situation due to concerns about supply chain vulnerabilities.

Past disruptions at Wentzville and other facilities have prompted competitors to reevaluate their sourcing strategies, improve inventory management, and strengthen supplier relationships to avoid costly shutdowns and production interruptions.

Industry-Wide Ripples

The Wentzville shutdown highlights ongoing challenges in the automotive industry, including fragile supply networks, logistics issues, and unreliable suppliers.

This situation emphasizes the need for improved operational resilience, supply chain diversification, and stronger contingency planning to effectively address future disruptions.

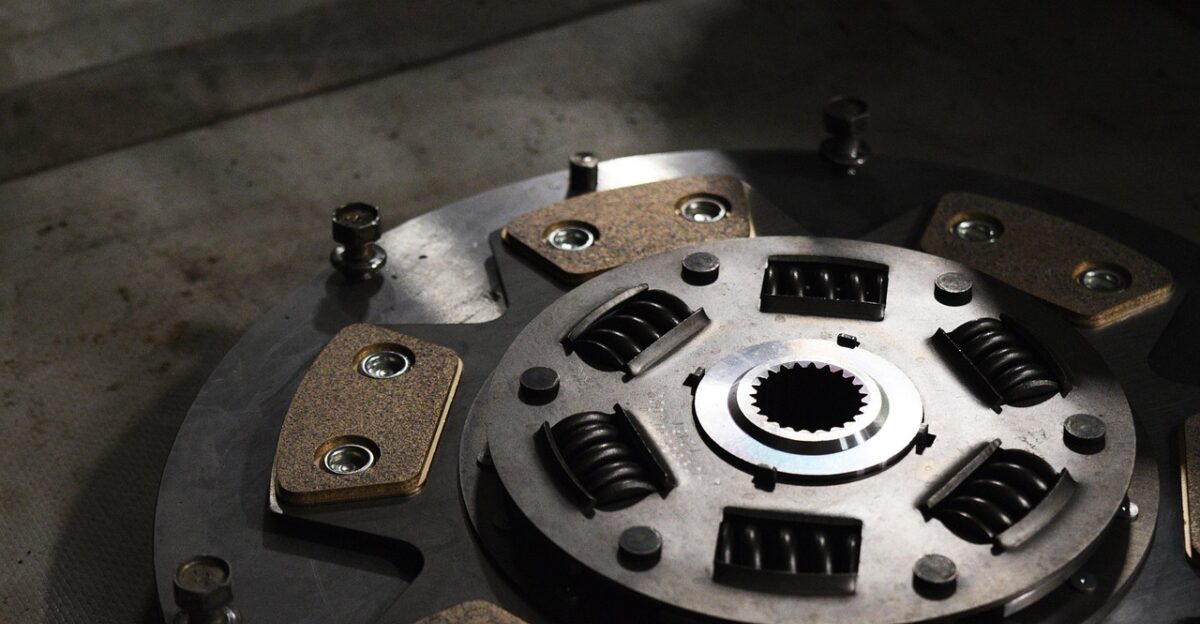

Supplier Mystery

General Motors has chosen not to specify which automotive part is in short supply, leading to speculation about the risks of single-source supplier relationships.

This lack of transparency complicates efforts for analysts and supply chain experts to accurately predict timing and prevent similar shutdowns in the automotive manufacturing sector.

Union Frustration

Union leaders have expressed growing frustration and concern with the recurring nature of these disruptive shutdowns, citing both persistent supply chain structural weaknesses and questionable management decisions that impact workers.

Employees are consistently left to shoulder the financial and personal burden of these operational interruptions, with limited recourse or compensation options available during these increasingly frequent and unpredictable production pauses and temporary facility closures.

Leadership Response

GM executives have publicly emphasized their commitment to resuming full production operations as quickly as possible while maintaining quality standards.

Plant Executive Director Eric Shelhorn and UAW Chairman Jon Daugherty jointly communicated detailed shutdown information to workers and stakeholders, signaling a unified—though admittedly strained—collaborative front between management and labor during this challenging operational uncertainty and workforce disruption.

Recovery Plans

GM aims to restart full production operations on October 20, 2025, pending complete parts availability and supply chain restoration. The company is actively working with multiple suppliers to resolve the current shortage situation and minimize any further disruptions to the production schedule.

However, industry experts note that the timeline for full recovery remains uncertain due to ongoing global supply chain volatility and unpredictable supplier performance.

Expert Outlook

Industry analysts and supply chain experts warn that current supply chain instability and operational disruptions may persist well into 2026.

While major automakers are investing significantly in improved logistics infrastructure and inventory buffer systems, industry experts and financial analysts remain notably skeptical about the speed of meaningful recovery and the effectiveness of implemented solutions to prevent future disruptions.

What’s Next?

Will this significant Wentzville shutdown prompt broader, meaningful changes in automakers’ strategic management of operational risk and supply chain vulnerabilities?

The automotive industry now faces tough, fundamental questions about supplier relationship management, inventory practices, production scheduling, risk assessment, and the long-term future of domestic U.S. manufacturing competitiveness in an increasingly volatile and unpredictable global marketplace.

Policy Implications

The Wentzville closure may reignite important political and economic debates over industrial policy priorities and domestic sourcing requirements for critical manufacturing sectors.

Lawmakers and policymakers could push for new government incentives, regulations, or programs to strengthen domestic U.S. supply chains and systematically reduce dangerous overreliance on overseas parts suppliers and international manufacturing dependencies that create vulnerability.

Global Repercussions

International suppliers, business partners, and automotive stakeholders are watching the Wentzville situation closely with significant concern and interest.

Major disruptions at important U.S. manufacturing plants can seriously affect global production schedules, international trade flows, supply chain coordination, and worldwide automotive market stability, potentially affecting manufacturing operations and business relationships across multiple countries and continents.

Legal and Environmental Angles

Temporary layoffs raise important questions about worker protections, contractual obligations, unemployment benefits, and labor rights during production interruptions.

Meanwhile, sudden production halts can significantly affect corporate emissions targets, environmental compliance requirements, waste management systems at large industrial facilities, and sustainability commitments made by major corporations to stakeholders, investors, and regulatory agencies monitoring environmental performance.

Shifting Perceptions

Repeated shutdowns and production disruptions fundamentally change how workers, investors, and the general public view job security and stability in traditional manufacturing sectors.

The long-held expectation of steady, reliable employment in automotive manufacturing is gradually giving way to a new normal characterized by increased volatility, uncertainty, and unpredictable work schedules that challenge traditional employment models and worker financial planning.

Industry at a Crossroads

The Wentzville shutdown represents more than just a temporary operational setback—it’s a clear signal that the automotive industry must fundamentally adapt to a world of ongoing uncertainty, supply chain volatility, and operational challenges.

How individual companies and the industry respond to these current challenges may ultimately shape the long-term future, competitiveness, and sustainability of American automotive manufacturing in global markets.