Martian regolith—the loose, mineral-rich soil covering Mars—offers a plentiful construction aggregate, but it lacks natural cohesion. Under NASA’s In-Situ Resource Utilization (ISRU) strategy, researchers are exploring binders that reduce reliance on Earth-supplied materials.

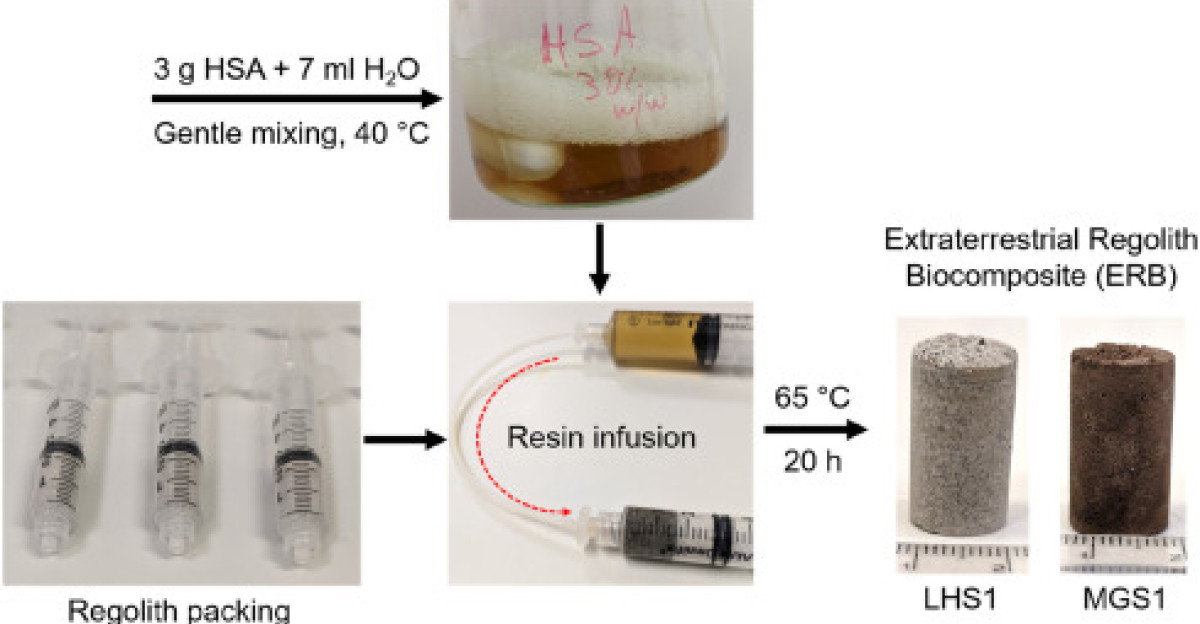

Laboratory studies show that human-derived compounds, particularly urea and proteins such as human serum albumin (HSA), can bind regolith into a concrete-like material known as AstroCrete. This approach leverages unavoidable human byproducts while addressing Mars’ extreme resource scarcity.

Historical Foundations

NASA’s interest in regolith-based construction dates back to lunar studies in the 1970s, when researchers evaluated sintering and sulfur-based concretes. While structurally promising, these methods required high energy inputs unsuitable for early Mars missions. The focus shifted toward low-energy chemical and biological binders.

By the 2010s, ISRU research expanded to include bio-inspired materials, culminating in experimental biocomposites that combine Martian soil simulants with organic binders.

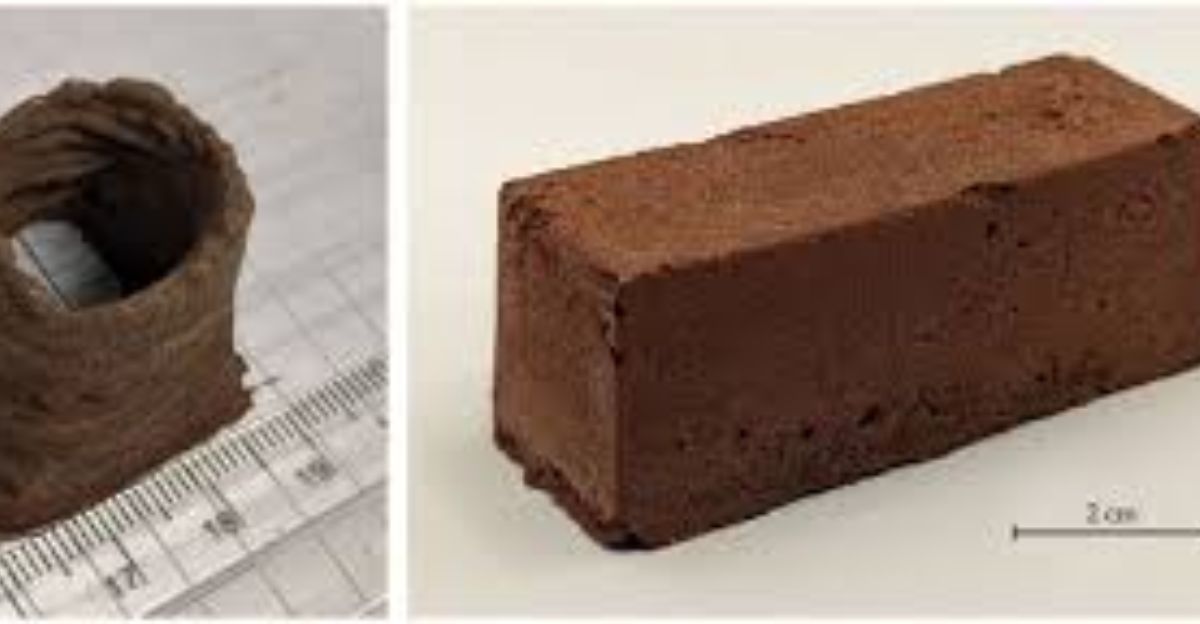

The AstroCrete Breakthrough

AstroCrete emerged from laboratory research demonstrating that HSA can act as a strong protein binder when mixed with regolith simulant. When urea is added, material plasticity improves and brittleness is reduced. Compression tests showed strengths comparable to conventional terrestrial concrete used in non-load-bearing applications.

While entirely experimental, AstroCrete represents one of the first low-energy, biologically assisted methods capable of forming solid construction elements from Mars-like soil.

Why Urea Matters

Urea plays a critical role by altering intermolecular bonding within the protein-regolith matrix. As a natural plasticizer, it allows protein chains to rearrange under stress, increasing toughness and compressive strength.

Urea is present in sweat and urine, making it a realistic byproduct for long-duration missions. Its inclusion significantly enhances material performance without increasing water demand—an essential advantage on a planet where liquid water is extremely limited.

Biological Construction Pathways

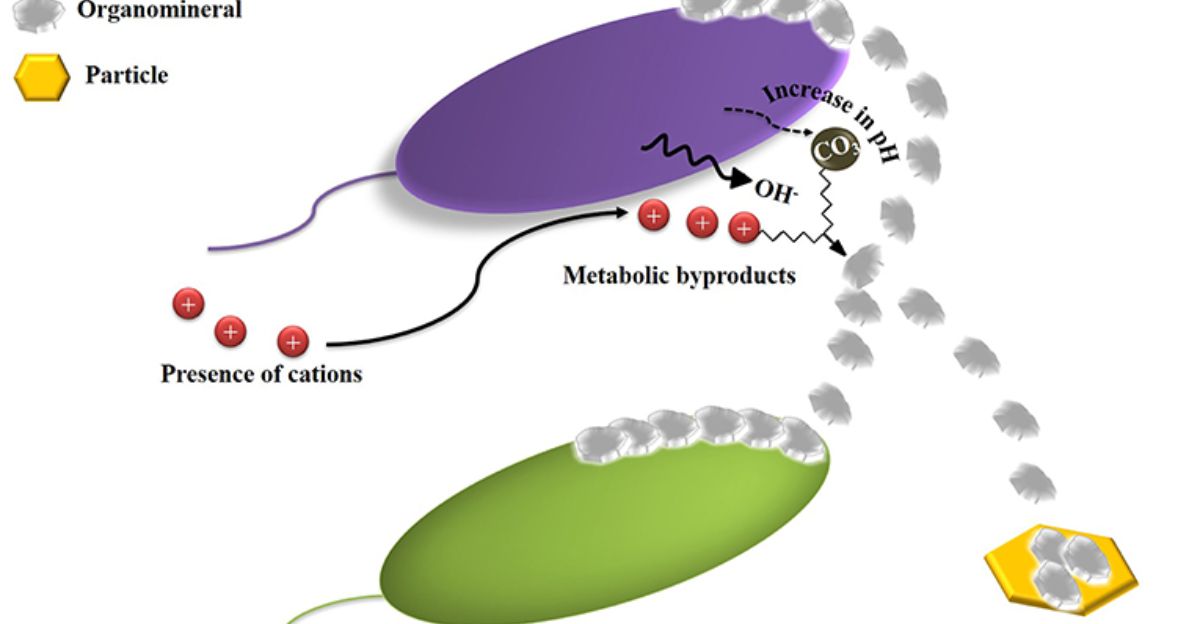

Beyond protein binders, researchers are also studying microbially induced calcium carbonate precipitation (MICP). This process uses bacteria to convert urea into carbonate minerals that cement soil particles together.

While current strengths are lower than AstroCrete, MICP offers a self-replicating, low-energy alternative. These biological pathways highlight how living systems could complement mechanical construction techniques in future Mars habitats.

Material Strength in Context

AstroCrete samples have demonstrated compressive strengths in the range typically associated with standard concrete used on Earth for sidewalks and low-rise structures. While not intended for skyscrapers, such strength is sufficient for pressurized habitats on Mars, where gravity is only 38 percent of Earth’s.

Lower gravity reduces structural loads, allowing materials with moderate strength to safely support enclosed living spaces.

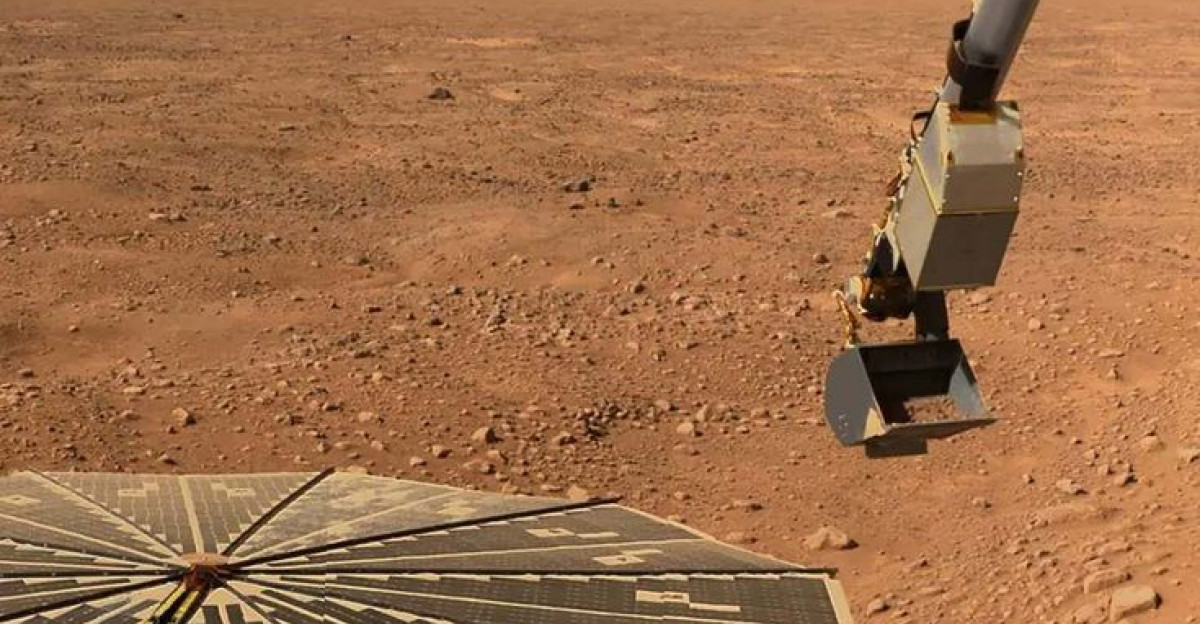

Regolith Characteristics

Martian regolith is composed primarily of silicate minerals, iron oxides, and fine dust particles. These particles pack efficiently but are chemically inert without a binder. Simulant studies show that grain size distribution and angularity influence final material strength.

However, regolith also contains perchlorates, which are toxic and must be removed or neutralized before use in construction processes involving human interaction.

Processing Challenges

Transforming regolith into building material on Mars involves multiple challenges. Extreme cold, low atmospheric pressure, and pervasive dust complicate handling and mixing. Any construction method must operate within sealed systems to protect astronauts.

Additionally, energy availability is limited, making low-temperature and low-power processes far more practical than traditional concrete curing or high-heat sintering.

Water Constraints

Water is one of the most tightly rationed resources on Mars. Conventional concrete relies heavily on water, making it unsuitable for early settlement phases. AstroCrete and similar biocomposites require minimal water, relying instead on protein denaturation and chemical bonding.

This dramatically reduces total water consumption and aligns with NASA’s priority to reserve water primarily for life support and fuel production.

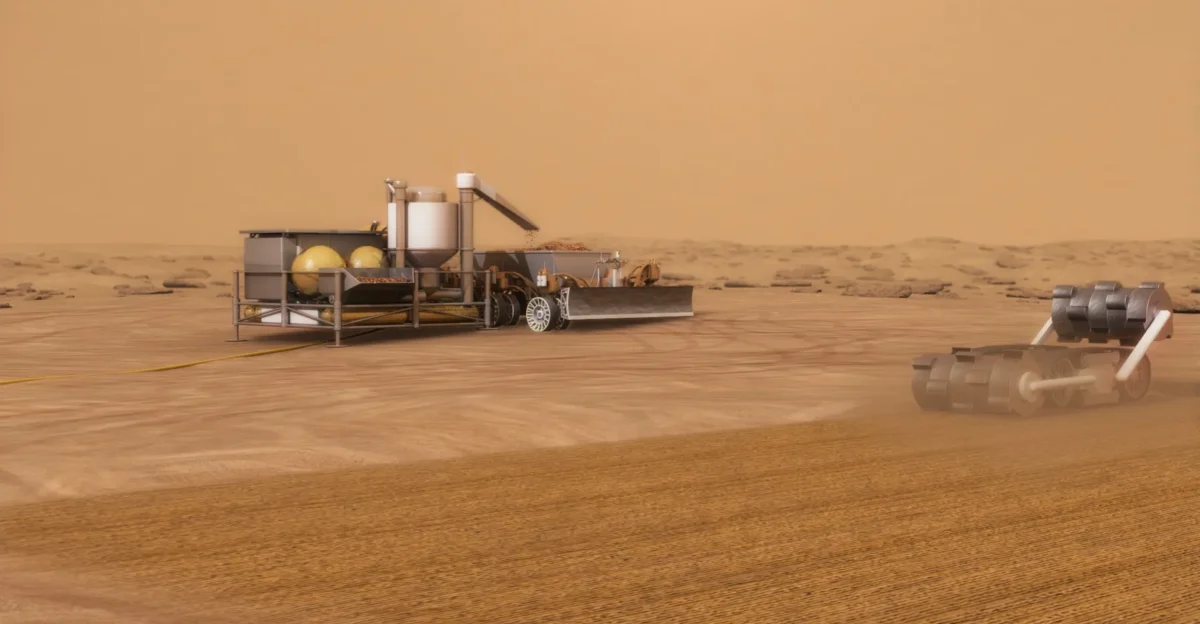

Production Feasibility

Laboratory models suggest that modest quantities of human-derived protein and urea could contribute meaningfully to construction over time. While extraction rates are limited, the approach is intended to supplement—not replace—other ISRU methods.

Automation, batching, and additive manufacturing techniques could gradually scale production, especially when combined with robotic assembly and pre-fabricated regolith components.

3D Printing Compatibility

NASA and its partners are actively developing regolith-based 3D printing systems. Biologically enhanced regolith mixtures are compatible with extrusion-based printing, allowing precise control over geometry and material placement.

This approach enables on-demand fabrication of walls, radiation shields, and structural reinforcements without transporting large prefabricated modules from Earth.

Radiation Protection Benefits

One of regolith’s key advantages is its effectiveness as radiation shielding. Thick regolith-based walls significantly reduce exposure to cosmic radiation and solar particle events.

Even moderate-strength materials can provide substantial protection when used in sufficient thickness, making regolith construction essential for long-term surface habitation.

Safety Considerations

All proposed biological binders must be non-pathogenic and stable over long durations. Research focuses on inert proteins and well-characterized bacterial strains already used safely in industrial applications on Earth.

Sterilization, containment, and redundancy are essential to prevent contamination of the Martian environment or onboard life-support systems.

Longevity and Durability

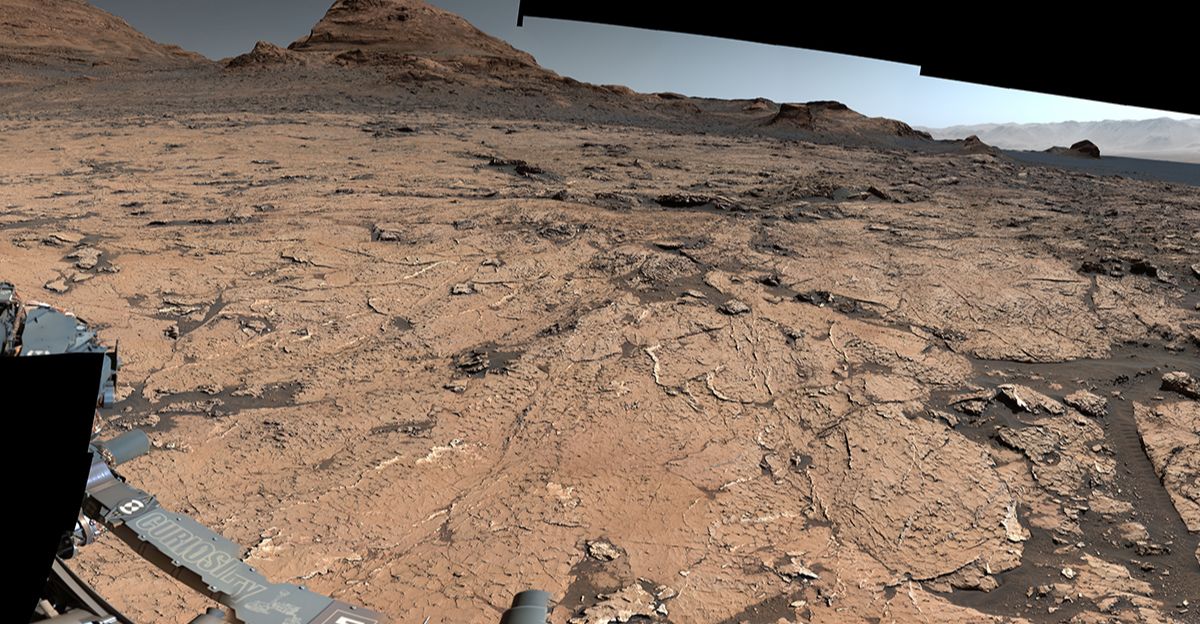

Mars presents unique durability challenges, including thermal cycling, UV exposure, and abrasive dust storms.

Early testing indicates that protein-regolith composites retain structural integrity under simulated Martian conditions, though long-term aging studies are ongoing. Protective coatings or layered construction may further enhance durability over decades of use.

Integration With ISRU Systems

AstroCrete-style materials complement other ISRU processes such as oxygen extraction, metal refining, and water recovery.

Construction waste can be recycled, and excess regolith from excavation can be repurposed immediately. This closed-loop approach reduces waste while maximizing the usefulness of every kilogram of material processed on Mars.

Economic Implications

Every kilogram launched from Earth carries enormous cost. Even modest reductions in imported construction materials translate into billions of dollars saved over the lifespan of a Mars program.

Human-derived binders effectively turn unavoidable biological byproducts into valuable infrastructure inputs, improving mission sustainability without additional launch mass.

Comparison With Alternatives

Compared to sintered regolith or sulfur concrete, bio-assisted composites require less energy and simpler equipment. While mechanical strength may be lower, the tradeoff favors reliability and resource efficiency.

These materials are best suited for habitats, interior structures, and shielding rather than high-load mechanical components.

Current Limitations

AstroCrete remains a laboratory-scale concept. Protein extraction, long-term storage, and large-volume production have not yet been demonstrated in space.

Researchers emphasize that the method is experimental and intended to complement, not replace, more conventional ISRU construction techniques as technology matures.

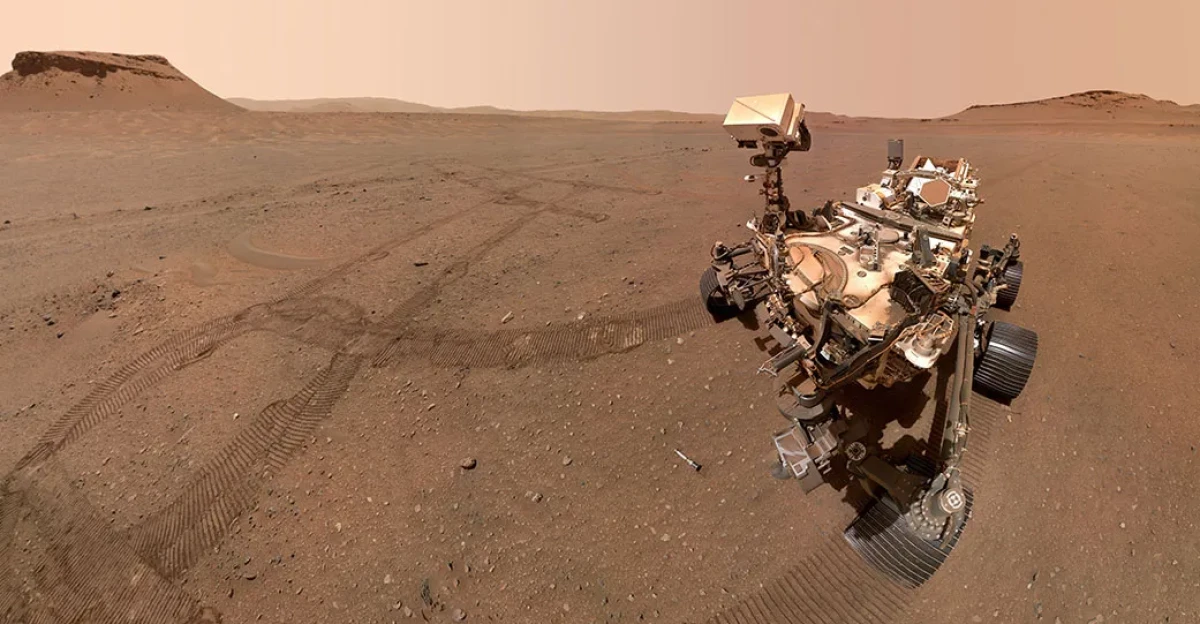

Path to Deployment

Before deployment on Mars, further testing is required aboard the International Space Station and in lunar analog environments. These tests will evaluate microgravity processing, automation, and material consistency.

Incremental demonstrations will determine whether human-derived binders can transition from experimental novelty to practical construction resource.

A Practical Step Toward Mars Habitats

Using Martian soil combined with human-derived binders represents a shift in how off-world construction is envisioned. Rather than importing everything from Earth, future explorers may rely on integrated biological and mechanical systems to build their own shelters.

While still experimental, this approach aligns closely with NASA’s long-term vision of sustainable, self-sufficient human presence on Mars.

Sources:

Title: Blood, sweat, and tears: extraterrestrial regolith biocomposites with in vivo binders, Publication: Materials Today Bio (2021), PMC.

Title: Microbial induced calcite precipitation can consolidate martian and lunar regolith simulants, Publication: PLOS ONE (2022).