The shutdown clock is already running. Inside an East Tennessee manufacturing facility, 136 workers now know their jobs will vanish between late April and the end of August 2026, following a WARN notice filed just days before the holidays.

The plant will wind down line by line, shift by shift, until operations cease entirely. Why this site was selected—and what that choice reveals about the industry—comes next.

Paycheck Shock

When the final shift ends, an estimated $7 to $10 million in annual wages will disappear from the surrounding region. Based on standard manufacturing pay, the loss of 136 positions removes far more than individual incomes—it strips spending power from grocery stores, landlords, repair shops, and local services.

In a rural labor market with few large employers, that sudden withdrawal threatens a ripple effect that spreads well beyond the factory floor.

A Major Player Steps Back

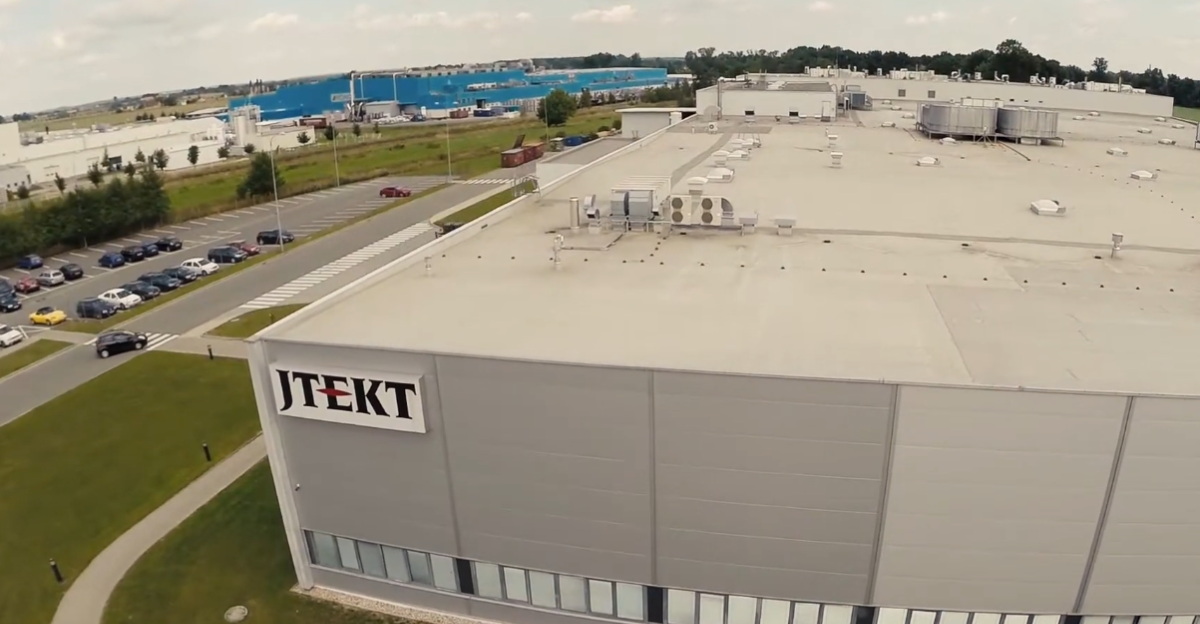

The company behind the closure is not a minor operation. It is a large automotive supplier with a nationwide footprint, operating more than 20 facilities across the United States and employing roughly 5,000 workers.

Its components are embedded throughout the auto supply chain, making it a familiar name to manufacturers. That scale makes the decision to shutter a single Tennessee site especially consequential for those on the ground.

Squeezed From All Sides

Traditional auto suppliers are facing mounting pressure as automakers move away from conventional engines. Declining demand for certain legacy components has left some plants struggling to justify continued operation.

Facilities built around older designs now compete in an industry rapidly shifting toward electric platforms, automation, and new technologies—leaving select locations increasingly vulnerable as product needs evolve.

Closure Confirmed

The outcome is final. JTEKT North American Corporation will permanently close its Telford, Tennessee, manufacturing facility through a phased shutdown beginning around April 30 and concluding by August 31, 2026.

A WARN notice filed on December 4 formally notified state officials that all 136 employees at the site will be laid off. The filing confirms the closure is not temporary and will not be reversed.

Local Jolt

Telford sits in Washington County, a region that has leaned heavily on manufacturing to stabilize its economy. Losing 136 industrial jobs at once delivers a sharp blow in an area where comparable positions are scarce.

Each layoff tightens spending, strains local services, and weakens municipal revenues. For a small community, the closure risks reshaping daily life long after the factory gates close.

Households Upended

Behind every job loss is a household forced to recalibrate. More than 136 families now face decisions about health coverage, savings, and education expenses as the shutdown clock ticks forward.

Some workers support children, others aging relatives, and many rely on stable manufacturing wages earned over decades. The phased closure stretches uncertainty across months, prolonging stress rather than offering a clean break.

Other Plants Operate

The closure does not mark a full exit from Tennessee. JTEKT will continue operating its Morristown and Vonore facilities, underscoring that the decision is targeted rather than statewide.

That contrast raises difficult questions for workers in Telford, highlighting how differences in product focus, costs, and demand can determine which plants survive—and which are sacrificed.

EV Era Pressure

As electric vehicles gain market share, demand for components tied to traditional engines and drivetrains continues to fade. JTEKT’s explanation mirrors a broader industry trend, where suppliers anchored to legacy technology face shrinking orders.

For plants unable to pivot quickly, consolidation becomes unavoidable. Facilities like Telford increasingly find themselves on the losing side of a structural shift reshaping automotive manufacturing.

Hidden Cost

The loss extends beyond paychecks. Removing $7–10 million in wages from the local economy can slow housing markets, reduce sales-tax collections, and pressure public services. Schools, clinics, and infrastructure projects all depend on a stable tax base.

When a single employer disappears, the impact quietly accumulates across institutions that once relied on its steady economic contribution.

Rapid Response

State and regional officials have initiated a rapid response effort to assist displaced workers. The Northeast Workforce Development Board has been notified to coordinate reemployment services, training programs, and benefits access.

While these programs can ease transitions, replacing specialized manufacturing wages in rural labor markets remains difficult, especially for workers nearing retirement or tied to the area.

Corporate Crossroads

For JTEKT, the closure reflects a strategic recalibration rather than financial collapse. Concentrating production at fewer sites allows the company to align operations with evolving demand and emerging technologies.

From a corporate perspective, the move may improve efficiency. For the Telford workforce, however, that optimization translates directly into unemployment and forced reinvention.

Searching Options

As the shutdown window approaches, workers may pursue transfers, severance, or retraining opportunities. JTEKT has indicated that transfer options and career transition support will be available.

Workforce agencies may steer displaced employees toward advanced manufacturing, logistics, or health care roles. Yet distance, age, and family obligations often limit how many workers can realistically relocate or retrain before layoffs take effect.

Uncertain Gains

Landing a replacement job does not guarantee comparable pay. Large automotive suppliers typically offer wages and benefits that exceed those found in many local service or warehouse roles.

Even as EV-related industries grow, skill mismatches and geographic barriers can leave workers underemployed. The long-term risk is a gradual erosion of middle-income manufacturing jobs in communities like Telford.

What’s Next?

By August 31, 2026, the Telford plant will be fully shuttered, leaving local leaders facing a difficult test. Can new investment arrive fast enough to replace 136 lost jobs and millions in wages, or will the closure mark a lasting contraction?

The outcome will signal whether rural manufacturing communities can adapt as the automotive industry accelerates into a new era.

Sources:

“JTEKT closure to affect 136 employees in Telford.” Times News, Dec. 7, 2025.

“JTEKT announcing 2026 closure of Telford plant.” SuperTalk 92.9, Dec. 5, 2025.

“JTEKT North America in Telford to close facility; more than 100 employees affected.” WCYB (NBC News), Dec. 4, 2025.