Across America’s Rust Belt and beyond, factory towns built prosperity on a single promise: stable, well-paying jobs for generations. From the 1970s through the 2000s, that promise collapsed. Plant closures eliminated hundreds of thousands of manufacturing jobs.

Entire communities lost their economic foundation, identity, and future. Today, despite revival efforts, these 15 towns continue to struggle with unemployment, population decline, crumbling infrastructure, and limited opportunities—a legacy of deindustrialization that continues to shape American inequality.

What Factory Closures Did to Local Economies

When a major factory closes, the damage spreads beyond the plant floor. Thousands lose their paychecks, immediately impacting retail, services, and housing markets. Property values drop, and tax revenues vanish, forcing cuts to schools, police, and infrastructure.

Suppliers and contractors often collapse. Banks tighten credit, and young residents leave. What remains are hollow downtowns and abandoned buildings. Communities must rebuild on a fraction of their former tax base, a process that can take decades.

The Human Toll on Workers and Families

Behind the closure statistics are real people: older autoworkers retraining for lower-wage jobs, families losing pensions and health coverage overnight, and generations witnessing the loss of financial security.

Stress, divorce, and substance abuse rise. Bright students leave for college and never return. Neighborhoods deteriorate as homeowners are unable to sell, and new residents are deterred from investing. The psychological toll is profound, reflecting the lost sense of purpose and identity that factory work once offered.

Why These Industries Collapsed

Factory closures were rarely random. Global trade allowed companies to move production to lower-wage countries. Automation eliminated repetitive roles, while foreign competition undercut the American steel and textile industries.

Mergers, bankruptcies, and corporate restructurings accelerated layoffs. Economic shocks and recessions further stressed heavy industry. Combined, these forces overwhelmed the 15 towns below, which were dependent on single employers, creating systemic, nationwide deindustrialization that reshaped entire regions and left lasting economic scars.

1. Janesville, Wisconsin – General Motors (GM Janesville Assembly)

Janesville centered its identity on GM for nearly a century, proudly calling itself “the city that motorized America.” When GM halted production in 2008 and closed the plant in 2009, more than 2,000 workers lost stable, well-paid jobs.

The closures affected suppliers, local stores, and public services. Janesville has added logistics and service employers, but wages rarely match old GM contracts, leaving many families still working to regain long-term security.

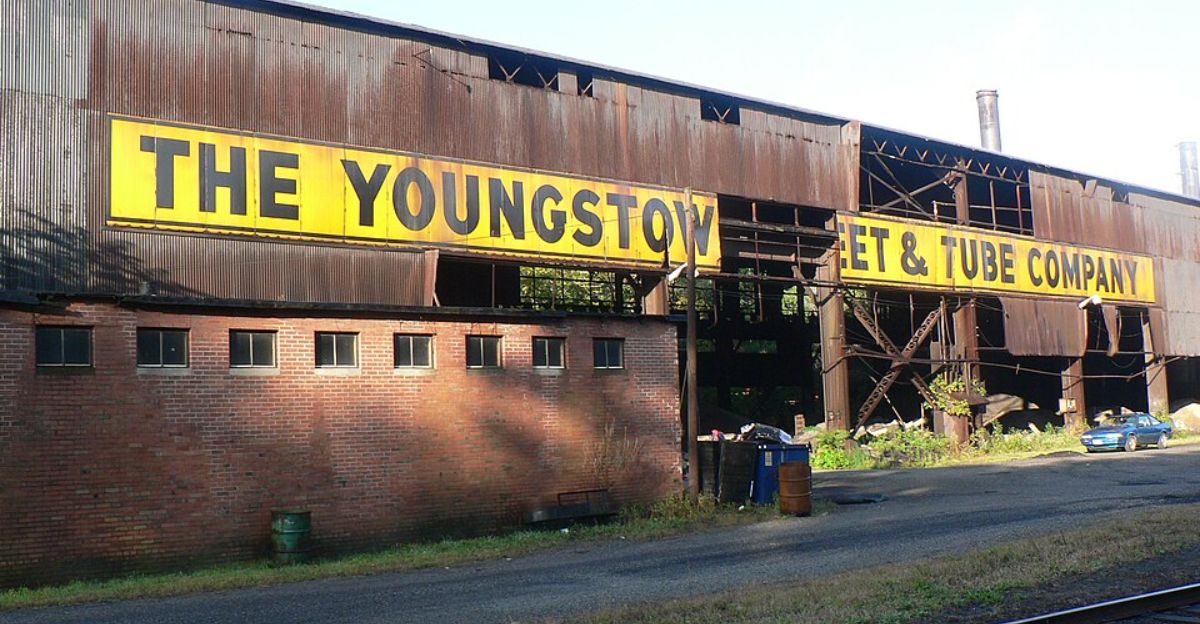

2. Youngstown, Ohio – Youngstown Sheet and Tube / Steel Corridor

Youngstown became a national symbol of deindustrialization after Youngstown Sheet and Tube shut its Campbell Works on “Black Monday” in 1977, eliminating thousands of steel jobs at once. The impact triggered population loss, a decline in the tax base, and an increase in poverty.

Despite revitalization attempts involving downtown redevelopment and tech incubation, income levels and population remain far below the peaks of the steel era, and many neighborhoods still reflect the deep wounds left by the collapse.

3. Galesburg, Illinois – Maytag Appliance Plant

Maytag’s refrigerator plant once anchored Galesburg’s middle class and employed more than 1,600 workers. When Maytag relocated production to Mexico, the Galesburg plant closed in 2004, eliminating union manufacturing wages that had supported stable households for decades.

Schools saw declining enrollment, property values fell, and many residents left. While Galesburg has grown its education sector and small-business activity, the loss of its industrial core remains difficult to replace.

4. Flint, Michigan – General Motors Autoworkers

Flint was once a centerpiece of General Motors, employing roughly 80,000 autoworkers and supporting a thriving blue-collar middle class. As GM reduced its workforce from the 1970s onward, Flint lost tens of thousands of jobs and large sections of its tax base.

The water crisis later intensified the city’s struggles. New investments in manufacturing and education are emerging, but poverty, infrastructure challenges, and population decline persistently shape daily life.

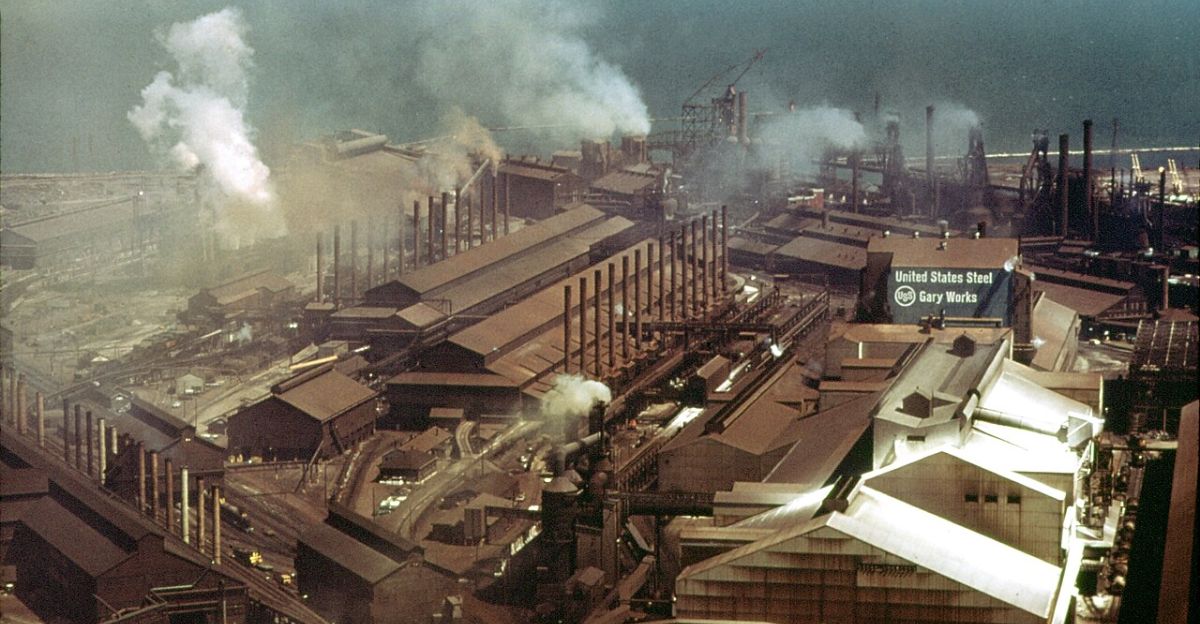

5. Gary, Indiana – U.S. Steel and the Steel Industry

Gary was founded in 1906 by and flourished in the steelmaking and heavy industry sectors. When competition, automation, and consolidation transformed the sector in the 1970s and 1980s, production contracted sharply, and the city’s population dropped by more than half.

Vacant properties, closed schools, and strained public services became widespread. Although the steel mill still operates and leaders promote diversification, Gary remains emblematic of long-term industrial decline.

6. Bethlehem, Pennsylvania – Bethlehem Steel

Bethlehem Steel once supplied metal for iconic bridges and skyscrapers and employed thousands across its vast local complex. Its 2001 bankruptcy erased paychecks and secure pensions, affecting workers and surrounding communities dependent on steel.

Parts of the plant now host arts venues, cultural attractions, and a casino. While downtown shows pockets of renewal, many families tied to steel still feel the effects of lost income and shifting opportunities.

7. Kokomo, Indiana – Chrysler and Stellantis Auto Plants

Kokomo rose with Chrysler’s transmission and components plants, which provided more than 10,000 jobs at their highest point. Layoffs, idled facilities, and Chrysler’s 2009 bankruptcy shook local economic stability and reshaped community expectations about manufacturing work.

New technology shifts and global supply disruptions have added fresh challenges. Kokomo maintains an industrial base, but the number of positions is fewer and more uncertain compared to when auto jobs offered reliable, lifetime careers.

8. Muncie, Indiana – BorgWarner, Delco, and Auto Suppliers

Muncie, known as “Middletown” in sociological studies, once thrived on industries like BorgWarner and Delco Remy, which employed thousands. Closures and downsizing from the 1980s to the 2000s dismantled much of its industrial economy.

Ball State University is now the largest employer, guiding Muncie toward a focus on education and services. Yet many neighborhoods face lower wages and fewer career opportunities for non-college workers, reflecting the retreat of manufacturing.

9. Anderson, Indiana – Delco Remy and GM Suppliers

Anderson was a central GM hub, home to Delco Remy, Guide Lamp, and multiple related plants. More than 20,000 auto jobs once supported the community. GM’s restructuring and relocation through the 1980s and 1990s erased most of these positions.

The population declined, tax revenues fell, and poverty rates increased. The city continues to attract logistics, healthcare, and smaller manufacturers, but has not fully regained its former wage base.

10. Detroit, Michigan – Big Three Auto Industry

Detroit became one of the world’s wealthiest industrial cities thanks to the contributions of Ford, Chrysler, and General Motors. Decades of job loss, automation, and residential flight weakened its economy and cut deep into city finances, culminating in a historic municipal bankruptcy in 2013.

Downtown and several neighborhoods have undergone meaningful revitalization. Many outer areas continue to experience blight, unemployment, and reduced public services, resulting in an uneven and incomplete recovery.

11. Dayton, Ohio – NCR, Frigidaire, and Manufacturing Base

Dayton, once a manufacturing and innovation powerhouse, was home to NCR, Frigidaire, and numerous automotive and aerospace suppliers. Major closures and relocations, including NCR’s 2009 headquarters move to Atlanta, resulted in the loss of thousands of quality jobs.

The city has expanded its tech, healthcare, and defense sectors. Still, wages and job access for workers without degrees lag behind those of the past, and many former factory neighborhoods continue to struggle.

12. Burlington and Greensboro, North Carolina – Burlington Industries (Textiles)

Burlington Industries was once among the world’s largest textile producers and employed tens of thousands across North Carolina. Globalization, offshoring, and trade shifts weakened the sector, leading to bankruptcy in 2001 and widespread mill closures.

Entire communities built around textiles faced deep job losses. Some specialized manufacturing and advanced textile operations have emerged, but wages and security remain weaker than during the height of union-influenced mill work.

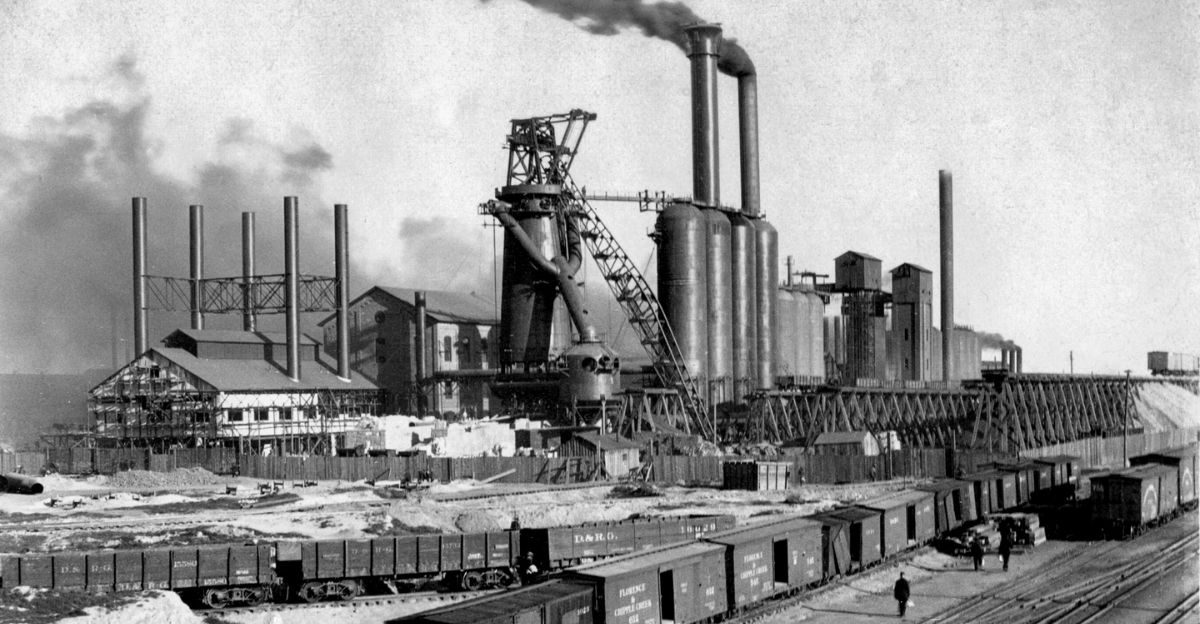

13. Pueblo, Colorado – Colorado Fuel and Iron Steel Works

Pueblo earned the nickname “Steel City” due to the CF&I steel mill, which once employed tens of thousands of people. Global price pressures, foreign competition, and ownership changes led to significant downsizing from the 1980s onward, resulting in a substantial decline in industrial employment.

Although the mill still operates under new ownership and the city invests in political and economic renewal, the shift has led to long-term wage stagnation and a diminished role for steel in the local identity.

14. Millinocket, Maine – Great Northern Paper Company

Millinocket grew around the Great Northern Paper Company’s massive mill, which offered generations of residents steady, well-paid work. As the North American paper market contracted, the mill shut down through a series of closures, with a major one in 2008.

Hundreds lost jobs in a remote area with few alternatives. Efforts in outdoor tourism, renewable energy, and redevelopment are promising, but economic replacement remains partial, and many residents still feel the loss.

15. Warren, Ohio – Steel and Metals Manufacturing

Warren was heavily tied to steel and metals manufacturing throughout the twentieth century. A long pattern of closures, including Warren Steel Holdings’ permanent shutdown in the 2010s, eliminated core industrial jobs and weakened the local economy.

Shops, schools, and housing absorbed the blow. New employers and distribution centers have opened, though typically at lower pay, making Warren a clear example of the challenges facing former steel communities.

Attempts at Revival and Why They Often Fall Short

Many towns tried to reinvent themselves: casinos, cultural centers, tech hubs, healthcare, and education-focused economies. Some progress is visible, with new employers, downtown revitalization, and modestly lower unemployment.

Yet new jobs rarely match past wages. Benefits are weaker, job security is limited, and younger residents continue leaving. Housing and infrastructure remain underinvested, leaving communities partially recovered but far from the prosperity they once knew.

What the Future Looks Like for Old Factory Towns

Old factory towns will not return to steel-era glory, but futures remain possible—different, humbler, but viable. Investment in education, remote work infrastructure, sustainable tourism, and quality-of-life amenities can attract residents and businesses.

Regional cooperation and supportive federal policy are crucial. Stabilization and modest growth are achievable, but chasing past industrial glory is futile. True success means building new identities and opportunities while leaving behind ghost industries.

Sources

Federal Reserve Bank of Chicago – Gary Profile community study

Federal Reserve Bank of Chicago – Detroit’s Bankruptcy: The Uncharted Waters of Chapter 9

City of Flint – Case Study: City of Flint, Michigan (municipal fiscal and economic conditions)

BBC News – Detroit becomes largest US city to file for bankruptcy (July 2013)

Reuters – Stellantis to temporarily lay off US workers as tariffs bite (April 2025 auto industry report)